Dutchronnie

Well-known member

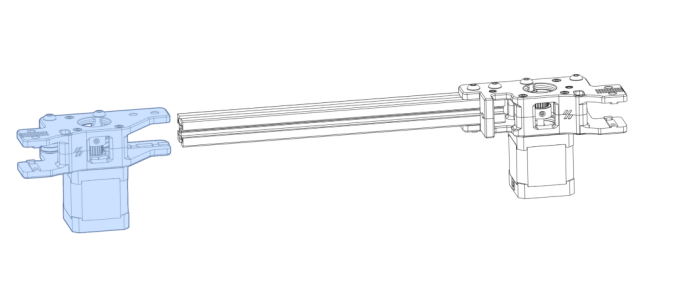

How to properly align the gantry?

When i put the extrusion of the X-axis in the a/b holder, and push the to the end, then the distance between the a/b dives is not good.

When i look on page 87 of the manual, i see some space between the extrusion ant the printed parts, but the manual doesn't tell what the distance of the gap must be.

When i put the extrusion of the X-axis in the a/b holder, and push the to the end, then the distance between the a/b dives is not good.

When i look on page 87 of the manual, i see some space between the extrusion ant the printed parts, but the manual doesn't tell what the distance of the gap must be.