Day 12: A whole week (roughly)

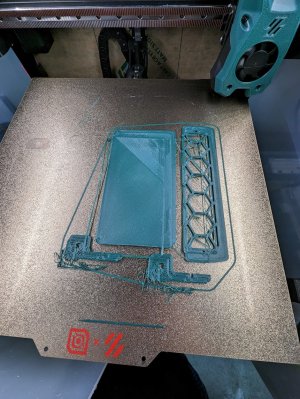

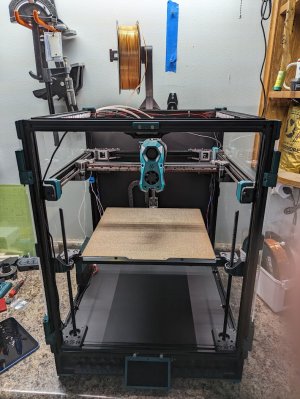

So immediately after I took that screenshot of the webcam the print failed with layer shift. And every print since then has failed the same way. Something went wrong with the printer mechanics.

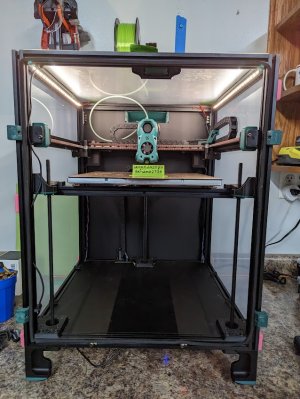

On Saturday I moved it back inside. And it refused to boot completely.

I hate Raspberry PIs, they seem to corrupt super easily. But at least I have a few of them lying around. Reinstalled raspbian and mainsail and etc on a new microSD card. Grabbed the printer configs from the old card... and it booted fine. *whew*. Everything was good again, except it still fails with the layer shift. Did the belt tension stuff again, double-checked the belt path, etc. No change. Welp. There was also a panic moment when I thought the X/Y front idlers were cracked, but I got that figured out pretty quickly that they are 2 pieces and just not matched perfectly.

One of my regrets on this build has been not doing a thorough cleaning on the linear rails when they arrived. So.... time to fix that. Tonight I tore the whole X/Y motion system apart. Pulled the rails off, and they are currently soaking in mineral spirits with quality lube waiting for them. I'll let them soak until tomorrow after work, and then lube and re-assemble. It'll be a pain, but it'll also be a better printer. I'll do the Z rails next.

I did order and receive a new camera, so I'll check the FOV on that one and maybe order another. It was cheap.

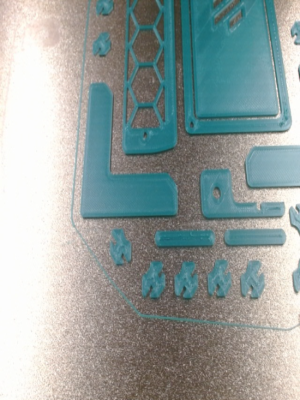

Before all this I did get the door hinges printed, some of the exhaust stuff printed. I like the doors, but these are the VHB tape version, so I need to reprint the bolted version for better stability. Made a list of things to print once its back together, so I'll be working through that list. Eventually.

E: screw it. Soak all the rails.