AlbatrossFPV

Member

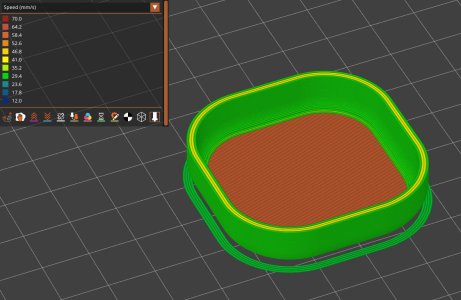

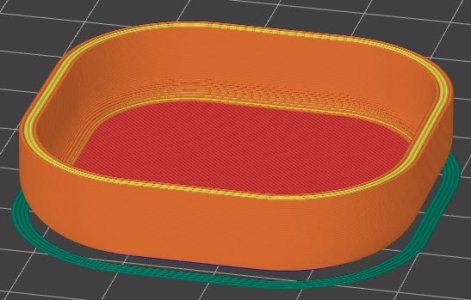

I've been having this specific problem for nearly as long as I've been using this printer. The issue is that when I try to print an overhanging fillet or chamfer (such as the test part pictured), the overhanging bit of the layer seems to curl up and continues doing this until the print reaches the straight, non-overhanging section of the print, when it seems to condense all of the curling into one glob (visible as the giant glob that runs along where the transition between overhanging and straight walls)

This happens equally along the entire outside edge of the print, seemingly no matter the size of the print (pictured test object is 40x40mm, but I have also tried 130x70mm with the same issue). The test part also has 2mm thick walls, in case that is good to know.

The printer I am using is a Voron 2.4 with Afterburner and a Phaetus Dragon hotend. I'm printing in Spool3D PLA and a 0.4mm nozzle. The model was sliced using PrusaSlicer 2.8.0. Some things I have tried, with next to no success are:

- Reducing print temperature (215C -> 190C)

- Increasing fan speed (50% -> 100%)

- Reducing speed (110mm/s -> 50mm/s)

- Increasing perimeter extrusion width (0.44mm -> 0.6mm)

- 0.2mm layers

- 3 perimeters

- 3 bottom layers, 4 top layers

- 20% gyroid infill

- No supports

- 50mm/s perimeter speed

- 60-70mm/s infill/solid infill speeds

- 0.5mm perimeter extrusion width

- 0.56mm external perimeter extrusion width

- 0.44mm extrusion width for all other features

- Spool3D PLA

- 0.93 extrusion multiplier

- 200C first layer

- 190C other layers

- 60C bed

- 100% fan

If any more information would be helpful, feel free to let me know. Thank you in advance for your help