sbman

Member

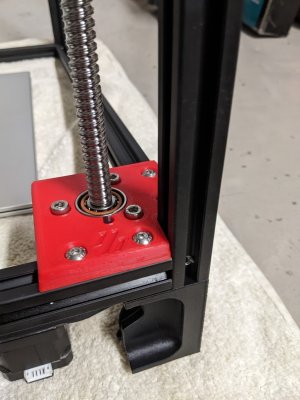

I've decided to build a Trident at it's max size of 350mm. Doing it self source and fabbing as much as I reasonably can because I enjoy that sort of thing. I've built CNC machines before this is just the first 3D printer I've done.

The plan is to keep it mostly stock, but with a USB toolhead, umbilical and an Eddy bed sensor.

The fusion and step files are for a 250. Is upsizing it as simple as adding 100mm to the parts that would need to scale or is there a source I am missing for a version of the model at 350?

Making parts like the top plate will need a fair bit of drawing modifications if I need to add length to the areas that expand but keep cutouts and slots the right size, it would not be as simple as scaling it up 1.4 times. I've got a large format laser cutter to use for cutting panels and such, but will need drawings that fit the machine size I am building.

The plan is to keep it mostly stock, but with a USB toolhead, umbilical and an Eddy bed sensor.

- Stealthburner toolhead w/Mosquito hotend

- Nitehawk USB toolhead board

The fusion and step files are for a 250. Is upsizing it as simple as adding 100mm to the parts that would need to scale or is there a source I am missing for a version of the model at 350?

Making parts like the top plate will need a fair bit of drawing modifications if I need to add length to the areas that expand but keep cutouts and slots the right size, it would not be as simple as scaling it up 1.4 times. I've got a large format laser cutter to use for cutting panels and such, but will need drawings that fit the machine size I am building.