- Printer Model

- Voron V2.4

- Extruder Type

- Other

- Cooling Type

- Afterburner

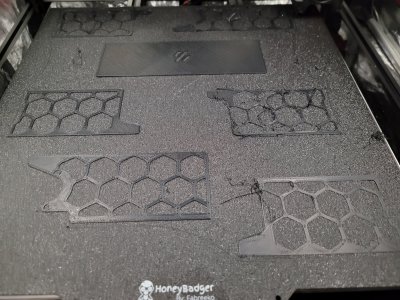

I am building a V2.4 printer and am trying to print the skirting. I have run through the calibration process and every time the job starts it fails shortly into the job. I get strings that get caught in the moving head and it either rips the object loose from the bed or gets tangled up and becomes a big mess.

I am using

E3D Revo Voron hotend

ABS filament

Honeybadger plate

Set bed at 110 Celsius

Set hotend to 230 Celsius

turned part cooling down and completely turned off

Attached shows the issue

I am using

E3D Revo Voron hotend

ABS filament

Honeybadger plate

Set bed at 110 Celsius

Set hotend to 230 Celsius

turned part cooling down and completely turned off

Attached shows the issue