ChrisA

Well-known member

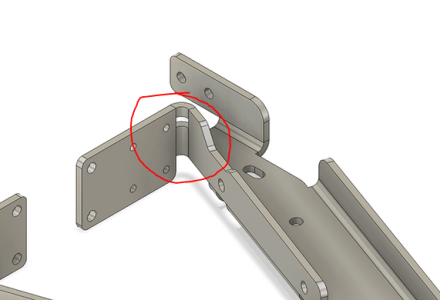

I'm building a V0.2 and just got to the point where you install the Kirigami bed support. The tabs that attach to the two Z-rails were badly out of alignment. I'd say "a few millimeters". There was just no way the holes could line up. I thought I'd have a hard time bending it straight. But no. I could bend those tabs by holding them with thumb and forefinger. I thought I'd need tools to bend the metal but it is so soft the danger is in over bending.

This means the entire pooint of the Kirigami is gone. It's purpose was to be stronger and more rigid than the printed ABS parts. But this is not the case.

If you look at the rear corners where the mount tabs turn there is very metal, a total cross scetion of 11mm x 2mm. The entitre fram, heat and bad is hanging by these tiny strips of metal. The reast of the frame is quite strong bu the critical part is so flimsy it can be bent with two fingers.

Perhaps itis flexible by design? Maybe so it will run without jambinmgof nbadly misalighn z-rails?

It also deflects under a light load, light finger pressure is enough to end the end of the bed a couple millimeters.

Did I just happen to get a bad/cheap one? Are other brands better?

I think I'll get one of these: https://www.aliexpress.us/item/3256805040703674.html

This means the entire pooint of the Kirigami is gone. It's purpose was to be stronger and more rigid than the printed ABS parts. But this is not the case.

If you look at the rear corners where the mount tabs turn there is very metal, a total cross scetion of 11mm x 2mm. The entitre fram, heat and bad is hanging by these tiny strips of metal. The reast of the frame is quite strong bu the critical part is so flimsy it can be bent with two fingers.

Perhaps itis flexible by design? Maybe so it will run without jambinmgof nbadly misalighn z-rails?

It also deflects under a light load, light finger pressure is enough to end the end of the bed a couple millimeters.

Did I just happen to get a bad/cheap one? Are other brands better?

I think I'll get one of these: https://www.aliexpress.us/item/3256805040703674.html