3dCase

Well-known member

I have tried prusaslicer on discord and they are not very helpful. I also tried reddit and again not helpful.

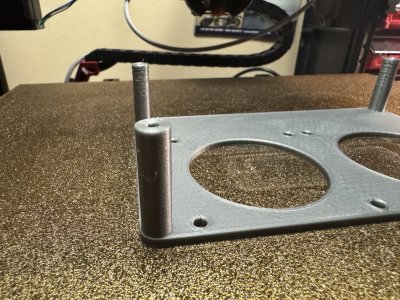

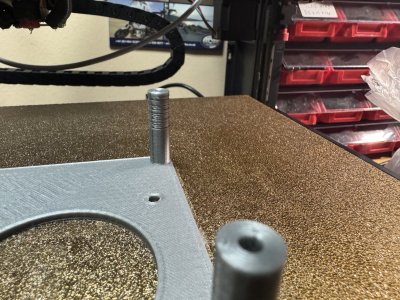

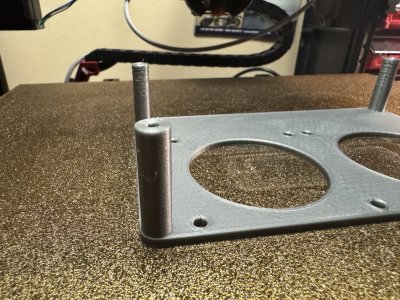

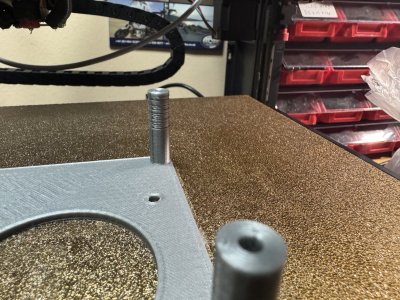

My PLA print suddenly has these missing layer sections at random points on slender protrusions on the top, when print time gets shorter. I tried slowing down the print but in the end it was printing at 17mm/min and still doing it. It also did it on rectangular protrusions, but when I put two different styles on the bed together it printed them fine. I changed several filaments and no difference. It is not height fixed and in one print it may do it only on some of the protrusions.

It is not clogged, it prints everything else perfectly without doing anything to the hotend or nozzle. Also it is random either on two out of the four or three out of the four pillars and at different heights. I do not think it is the machine but I have printed other stuff at that position and heigth and no trouble. It only happens on these slender pillars. I also reduced cooling since I run a cpap and it is known to be capable of too much cooling. But nothing works. I have also tried max cooling and upping the temperature but again no difference. Last was the blue calibration crosses which are 100 mm high. I looked closely when it does this and one layer it prints everything ok and the next layer it seems to not print, or partially print the perimeter while the solid infil is perfect every layer. Also on these crosses it starts exactly there where the infil changes to solid infil every time. But on the other pillars they where completely solid infil. At one point I thought my reverse bowden tube was kinking too much so I fixed it and eventually removed most of it. The filament is now fed through 4 ball bearings and does not get snagged anywhere but it did not change this problem. I am stumped.

Anybody any idea where to try next to get some improvement? PLA at 205 degrees. Fan starts at 20% (on all the time except first 2 layers) and max on 40% except for bridges (bridges fan speed is 50%). if print time is under 60 seconds per layer, enable fan. if print time is under 20 seconds per layer, slow down the speed. It was set to a minimum of 10 and it printed these round pillars on 17. I am lost for the moment as to what to do next.

My PLA print suddenly has these missing layer sections at random points on slender protrusions on the top, when print time gets shorter. I tried slowing down the print but in the end it was printing at 17mm/min and still doing it. It also did it on rectangular protrusions, but when I put two different styles on the bed together it printed them fine. I changed several filaments and no difference. It is not height fixed and in one print it may do it only on some of the protrusions.

It is not clogged, it prints everything else perfectly without doing anything to the hotend or nozzle. Also it is random either on two out of the four or three out of the four pillars and at different heights. I do not think it is the machine but I have printed other stuff at that position and heigth and no trouble. It only happens on these slender pillars. I also reduced cooling since I run a cpap and it is known to be capable of too much cooling. But nothing works. I have also tried max cooling and upping the temperature but again no difference. Last was the blue calibration crosses which are 100 mm high. I looked closely when it does this and one layer it prints everything ok and the next layer it seems to not print, or partially print the perimeter while the solid infil is perfect every layer. Also on these crosses it starts exactly there where the infil changes to solid infil every time. But on the other pillars they where completely solid infil. At one point I thought my reverse bowden tube was kinking too much so I fixed it and eventually removed most of it. The filament is now fed through 4 ball bearings and does not get snagged anywhere but it did not change this problem. I am stumped.

Anybody any idea where to try next to get some improvement? PLA at 205 degrees. Fan starts at 20% (on all the time except first 2 layers) and max on 40% except for bridges (bridges fan speed is 50%). if print time is under 60 seconds per layer, enable fan. if print time is under 20 seconds per layer, slow down the speed. It was set to a minimum of 10 and it printed these round pillars on 17. I am lost for the moment as to what to do next.