- Printer Model

- Voron Trident

- Extruder Type

- Clockwork 1

- Cooling Type

- Stealthburner

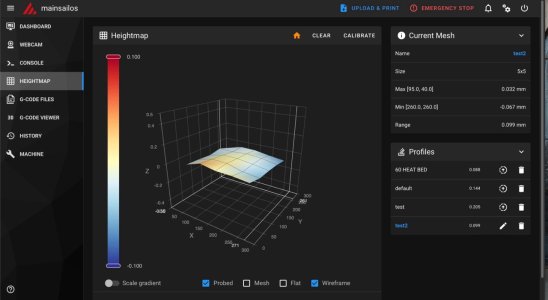

I build my LDO trident 12 months ago and has been printing very nice prints with very good quality, but I’ve always had a few bed issues where on the left hand side the first layer never seams squashed enough. So basically I used the right side of the bed and never worried about it as was always going to do the klicky probe mod and a few others and thought I’d sort it then.

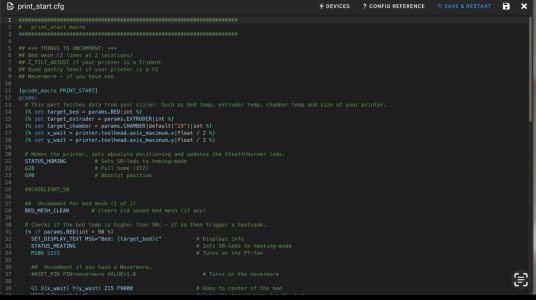

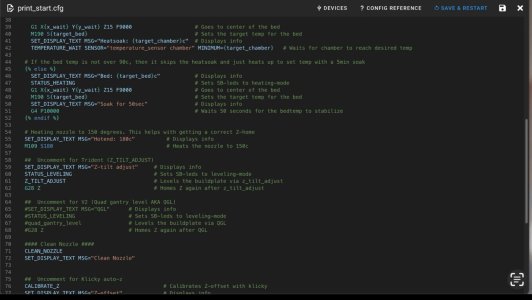

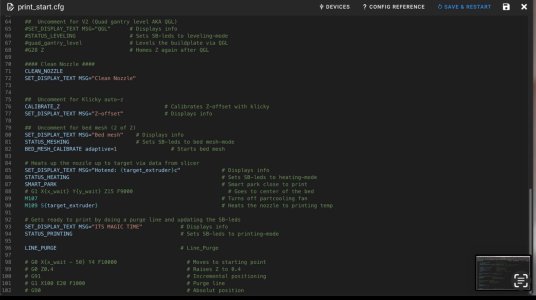

So after several hundred hours of printing it’s time to have a maintenance overhaul and do the klicky probe and inverted electronics etc.

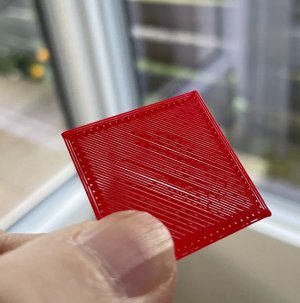

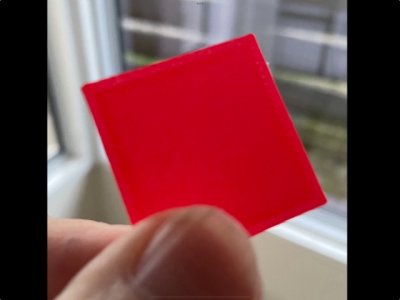

so did every thing I wanted and klicky working perfectly and did the Z-Cal macro upgrade etc and all working fantastically, but still the left side looks like this and second pic is middle and right side look like..

I’ve tried things like putting a piece of paper on the left side under the build sheet to pack it up, but made no difference which is what I though as the z tilt would fix that to make it flat again.

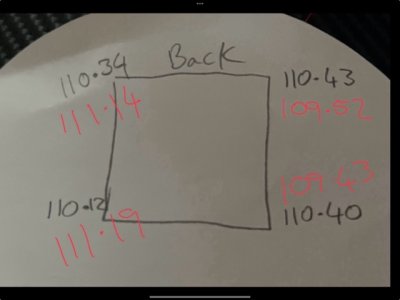

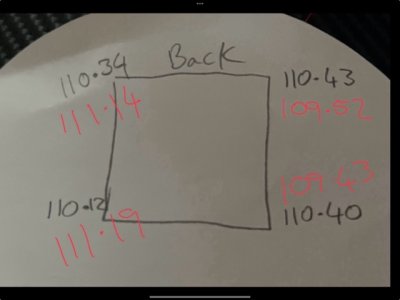

Then reading through the forms I seen someone talking about adjusting the extrusion holding the X linear rails. So I checked them and they were pretty spot on with the gaps all at 110mm when I used the calipers to measure them. So I took the left side up to 111 and the right side down to 109 to see if this might bring the left side back down. Sizes are here in this pic for you to compare.

This made no difference and now I’m scratching my head for what you experts might have in mind of what my issue could be, or am I just being far to fussy.

Thanks for your time.

So after several hundred hours of printing it’s time to have a maintenance overhaul and do the klicky probe and inverted electronics etc.

so did every thing I wanted and klicky working perfectly and did the Z-Cal macro upgrade etc and all working fantastically, but still the left side looks like this and second pic is middle and right side look like..

I’ve tried things like putting a piece of paper on the left side under the build sheet to pack it up, but made no difference which is what I though as the z tilt would fix that to make it flat again.

Then reading through the forms I seen someone talking about adjusting the extrusion holding the X linear rails. So I checked them and they were pretty spot on with the gaps all at 110mm when I used the calipers to measure them. So I took the left side up to 111 and the right side down to 109 to see if this might bring the left side back down. Sizes are here in this pic for you to compare.

This made no difference and now I’m scratching my head for what you experts might have in mind of what my issue could be, or am I just being far to fussy.

Thanks for your time.