Yes there always comes a point at which you need to decide and it is hard for somebody else to make up your mind. What you are doing is good but you can take it too far. At some point you are comparing apples with pears and trying to decide which is best. At that point it depends on weather you want an apple or you would like a pear more, its up to you that moment.

I understand what you means. Once you end up with apples and pears, sometimes you'll like to eat apples, other times pears. Unfortunately I can't afford such luxury, so a Voron is a mandatory choice. Hovewer, I must admit that, on pair of price, I would have had very hard times to decide between the twos.

As a starter note, that sensor is not a beacon as such, it is a most likely a clone and you cannot take beacon specifications and apply them. It is a shame you cannot find the real beacon, for instance from Jake 3d somewhere, because the beacon is absolutely stunning. My brother just installed one and the accuracy and speeds are mind blowing. Second for accuracy I believe would be the cartographer. Not up there with the beacon for accuracy but speed is the same so all in all way good enough for 3d printing. I cannot say anything about your found product, it could be a beacon with a rebrand on it but I doubt it.

Ok, it looks like this is something for which I must be very careful. The first thing I learned is that I should prefer Beacon and is not easy to distinguish it with Cartographer because they look the same included the one I found on AE. And when clones are involved, specs must be carefully checked because there's no guarantee they match the offficial ones.

So let start with the easist way. I found Beacon in stock from the official

store. Not sure, but for our StealthBurner + Galileo, I suppose we need variant D (not the H), standard profile, 6ft cable (included). It's $80 and between shipping and import taxes is going to be at least 3 times more expensive than the one I found on AE and in any case too much money for a tiny board like that (more expensive even than Octopus Pro + drivers). I can't find any Beacon probe from the Jake3D store, but I suppose it would be even more expensive.

I'm afraid my only option are clones and from what I see, even official Beacon has similar issues:

WARNING: Requires a conductive surface or substrate on printer bed to work. Bed stacks that include oversized fixed magnets are not recommended and may not work with Beacon.

May I ask what kind of bed and magnets size your brother uses with its Beacon? May be the same configuration also works with clones.

I never used the Galileo so I cannot say with what tooheads it is compatible. Yes I desin my own 100% and I always try to use a metal toolplate. Before now I also made my own metal tooplates but now there are many on the market. One of the reasons I went with the cartographer because they have their own metal toolplate made for it. unfortunately it did not fit my voron, because I think mine is a bit older and it had two linear rails for x axis, but I converted mine to one big x rail and modified the toolplate. This is not an option that is good for everybody because I have the use of advanced equipment at work. Without that I would not do these things.

Our friend

explained well why I should not be worried about compatibility. So, one problem (and a big one) less. Isn't 100% metal going to be too much weight? What's wrong with ABS? From what I've read, this is an area where we should try to reduce weight as much as possible. In any case, without a CNC machine, my only option is the regular way.

I think you might be right. Your could have been R1. Can't find the link, but I remember it was R2 the version with the major changes to the linear rails you mentioned.

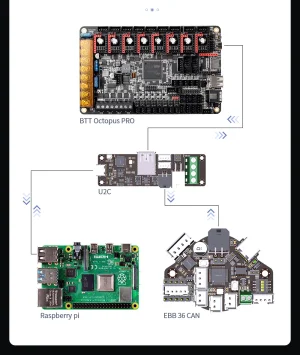

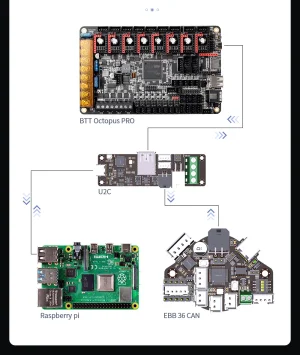

Choice of canboard I again cannot help I am afraid. All I can say is that next time I do a canbus machine I will probably use the octopus again and utilise the onboard. Simply for ease of use and compact controler.

You means Octopus Pro + EBB, right? From what I saw, even the lowest Mellow Fly is onboard driver. The Pro suppports 2240, a version that I've never taken care of until NoGuru joined the thread and

talked about it.

Can you confirm your EBB required a mod in order to fit your SB? This does not seem required with Mellow.

The U2C board does add wiring and with that comes questions and thinking about how to position them and route those wires efficiently. Next time I will probably like to be without those things.

Yes, and an extra communication layer (USB) is very bad. Something that I also want to avoid, but I'm wondering if this is a limitation of the Octopus rather than the CANBus boards:

Seems that the USB adapter is needed in any case, but stupid question: can't we just move it in the electronic bay and fix at least the wires issue?

This thread was about Octopus vs Fly Gemini and some people quickly recommended to stick with Octopus and they're probably right at least for simpler scenarios. Right now I see the Fly Gemini supports CANBus natively (cb port directly on board). Are we sure Octopus is still a better choice? No raspberry needed in fly gemini, integrated wifi, native canbus etc. There are only four slots for drivers, but they have a 4 slots expansion board.

Don't know what to say.

I wish you all the best with your choice making. I think you know enough of it, and what is stopping you know is simply your own demons.

Yes and they are so many

1) What am I going to use it for? Based on this chose a hotend that is good enough with regards to flow and will give you the right nozzle selection. For years the REVO Micro was good enough for me, now I stepped up to the Phaetus rapido UHF.

I should probably check better, but a complete Revo kit is about $40 cheaper than a Rapido. A good saving, but I feel like the hotend is the last part where one should go cheap. What I learned is that Rapido requires hot-tightening (240+°C) for nozzle swaps. Need to investigate on how much this can complicate usage. In any case I'll have to live with it.

2) How big does it need to be? Consider also that some mods will take away space! Also look at your available space, a giant 520 mm cubic is larger in real life then most people realise. This is the size of the V2.4-350. It is huge plus if you mount a camera and you put your roll of filament somewhere you need space.

Well, as long as mods do not reduce the print size I think I should be perfectly fine with it. I don't need a portable printer.

Camera is an upgrade I plan for the future. Modern cameras are very tiny, so I hope to not have to worry about space.

3) Available spare parts. You already said you have trouble sourcing some so obviously this is important.

4) Not in the least your skills. Building one of these is a big commitment and will be frustrating at times. Make sure you know where to find help and advise and that you have the right tools available. The tools they supply with parts are meant for one use only. In my case they go in the bin instantly. Also to build one means you will temporarilly need even more space! you will be rotating and flipping this thing regularly until it is done.

I would say is more like I can't source a particular part at any time. I have to wait the right time, nothing unmanageable with a bit of patience.

Believe me, when you have already spent months to design your build you get so frustrated to a point that you see as pure fun any issue that may occur during the build. Although I've checked around 80% of the BOM list, I had no chance to see such "one use only" tools you're talking about. Only hope to hit the target with a single shot.

I already know the build will have to enter into "stand-by mode" for a reason or another several times. I'm prepared for this. Thanks for all your tips, very precious!

I enjoyed this thread so far so I will revisit back and see how things progressed af course. And when there is updates on the controller I will mention that too.

Same for me! If I ever manage to determine the right parts to buy (I still have big doubts if I should go 100% BTT, Mellow or a mix of the twos and the probe is likely to be postponed on build completion if I can't find a suitable one now) I'll open a new thread to list the parts I'm going to buy. Many stock parts will ptobably need to be changed in order to be used in my custom build and I feel this is where I'll probably end up with mistakes.

Thanks again