scharkalvin

Member

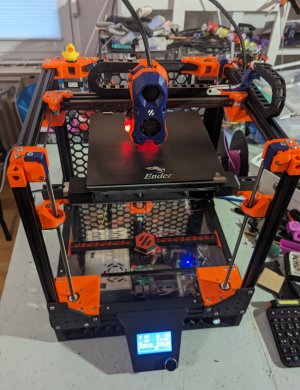

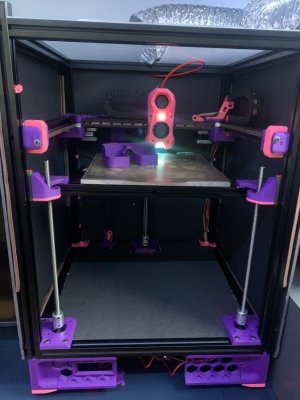

I've been seeing a lot of "Unrepaired Ender 3's and 5's for sale on ebay. I also own an Ender 3 that I'm about to try with Klipper. I've already changed out the hot end and the bed build surface. What has been going through my mind is the following: A. I'd like to add a second Z drive motor/screw so I could better support a direct drive extruder. but then... B: I should get rid of the plastic wheels and v slot linear bearings and replace them with propper rails and ball bearing movements. Then... C: wouldn't a conversion to Core XZ make more sense than a second Z drive screw? At this point, D: might as well do a complete Switchwire mod. Of course, this could all be done piecemeal, one bit at a time.

I have no need (or desire) to print in ABS, other than to print parts for a printer that could print in ABS (IOW, a fully enclosed printer), so would PETG be OK to print the conversion parts in, with the assumption that the printer won't ever be enclosed in a heated chamber? (All of the parts for a previous RepStrap were printed in PLA and PETG, and that printer never had a printed part fail.)

Now, as for those Ender 5's: I've seen an Ender 5 conversion to a Voron 2.4, but how about a Trident conversion? Finally, would there be any sense in a floating gantry version of a Trident?

I have no need (or desire) to print in ABS, other than to print parts for a printer that could print in ABS (IOW, a fully enclosed printer), so would PETG be OK to print the conversion parts in, with the assumption that the printer won't ever be enclosed in a heated chamber? (All of the parts for a previous RepStrap were printed in PLA and PETG, and that printer never had a printed part fail.)

Now, as for those Ender 5's: I've seen an Ender 5 conversion to a Voron 2.4, but how about a Trident conversion? Finally, would there be any sense in a floating gantry version of a Trident?