Thank you. As soon as I have the machine back up and running I will make those changes to my print start macro. I'll admit, I grabbed that macro from discord I think it was. I've only changed a few positions and added the bed mesh.Looks like a useable PRINT_START. Some suggestions (though none of this helps with an inconsistent first layer):

- The second G28 after the Z_TILT_ADJUST can just home Z with G28 Z to shave a few seconds.

- Any particular reason why you turn off fans with M107?

- The G92 E0.0 after M109 can be removed since extruder hasn't moved from the previous G92 E0.

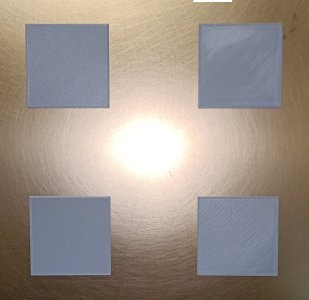

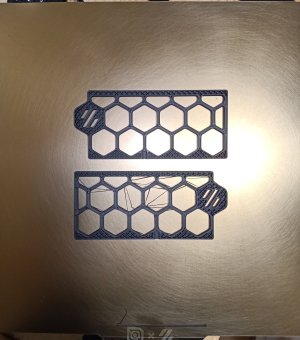

Hm... The first layer kinda looks acceptable to me. The unevenness might be caused by a slightly tilted nozzle? is your hotend perpendicular? Do you see a similar thing happening with top surfaces as well?

Yes, I agree. First layer doesn't look too bad in those photo's. Those were after I adjusted the y extrusions I think. Plus, the camera man (me) didn't do a great job of highlighting what I can see with my eye.

Thanks again for your suggestions!