wham

New member

Hey there, folks! I'm pretty new to all this, and still testing stuff out. Recently built my Voron 2.4 300 (and am working on a build log video which I'll post in the appropriate channel later) and have already gotten some fine prints out of it, but as I try to fine tune settings I occasionally stumble on an issue as seen in the attached images. I'm using PrusaSlicer 2.6.0 for my slicing and have been iterating on my profiles there, making changes, testing results, revering where I end up reducing print quality noticeably.

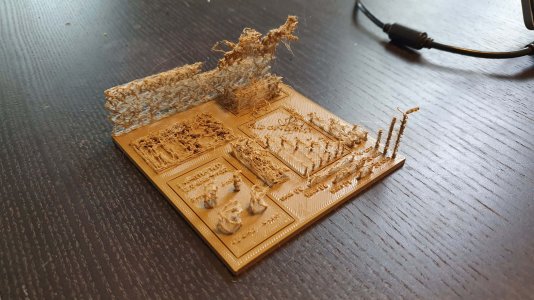

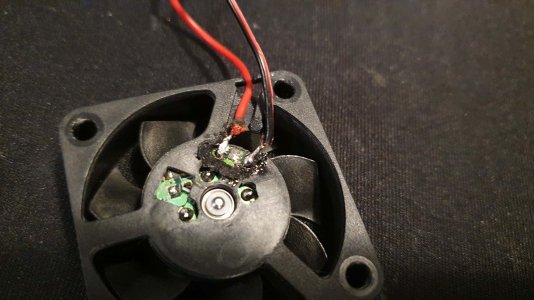

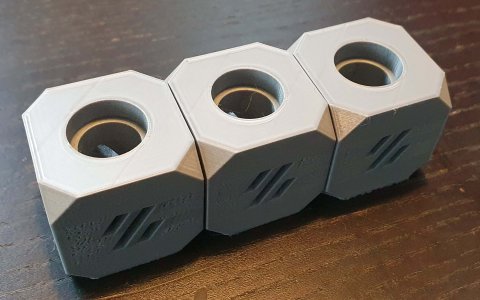

As you can see, it seems that the prints are being made in the right places and shapes, but the output isn't quite solid, sometimes leading to mostly air, sometimes just leaving little gaps in the output piece.

I've been adjusting print speeds, mostly lowering them to see if I can improve quality for smaller and more intricate pieces, and also testing out settings for retraction (to help smooth out the output pieces and reduce stringing) and cooling settings (most common issue I had early on was pieces curling up and coming off the build plate, and as I resolved that I began to see more drooping on overhangs).

I'm not expecting some miracle one step solution here, but I'd be happy to hear some suggestions on what I should try and what might have worked for others with the same kind of issue.

Alternatively, if you have PrusaSlicer profiles you are using to print on a Voron 2.4 300, I'd be curious to see what settings people are using as those can give me ideas on what to try and tweak.

As you can see, it seems that the prints are being made in the right places and shapes, but the output isn't quite solid, sometimes leading to mostly air, sometimes just leaving little gaps in the output piece.

I've been adjusting print speeds, mostly lowering them to see if I can improve quality for smaller and more intricate pieces, and also testing out settings for retraction (to help smooth out the output pieces and reduce stringing) and cooling settings (most common issue I had early on was pieces curling up and coming off the build plate, and as I resolved that I began to see more drooping on overhangs).

I'm not expecting some miracle one step solution here, but I'd be happy to hear some suggestions on what I should try and what might have worked for others with the same kind of issue.

Alternatively, if you have PrusaSlicer profiles you are using to print on a Voron 2.4 300, I'd be curious to see what settings people are using as those can give me ideas on what to try and tweak.