Roryhopcraft123

New member

***** SOLVED - wrong sized inserts *facepalm* *******

Hey All,

In just starting to put together the pieces for a Voron 0.2.

I have an Ender 3 V3 SE, in an enclosure with updated hot end. Printing ABS doesnt seem to be an issue. Calibrating the temperature and retraction, and using magigoo. Print quality looks good with no warping or layer issues.

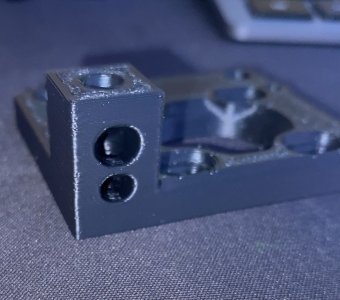

Holes and measurements all seem fine… except… vertical holes for heat inserts…. The holes for inserts parallel to build plate are great its just the ones perpendicular. They are so big the heat insert just falls in and out!

I have adjusted expansion values and hole tolerances in Cura down too -0.3mm. No luck still too big! Flow, temperature and speed all seem ok too. 5 times ive tried to print the Drive Frame Upper and everyone - hole too big….

Any suggestions welcome! How do i get it to be the right size for the insert!

Cheers

Hey All,

In just starting to put together the pieces for a Voron 0.2.

I have an Ender 3 V3 SE, in an enclosure with updated hot end. Printing ABS doesnt seem to be an issue. Calibrating the temperature and retraction, and using magigoo. Print quality looks good with no warping or layer issues.

Holes and measurements all seem fine… except… vertical holes for heat inserts…. The holes for inserts parallel to build plate are great its just the ones perpendicular. They are so big the heat insert just falls in and out!

I have adjusted expansion values and hole tolerances in Cura down too -0.3mm. No luck still too big! Flow, temperature and speed all seem ok too. 5 times ive tried to print the Drive Frame Upper and everyone - hole too big….

Any suggestions welcome! How do i get it to be the right size for the insert!

Cheers

Attachments

Last edited: