We recently built a new Voron 2.4, and for the first couple of weeks, we were printing PLA, and everything looked good. Then we started to print with ABS, and prints were not coming out as good as we wanted. In the process of fine-tuning, a defective Hot End fan caused a full meltdown of the hot-end assembly. Skipping forward, we replaced all the damaged parts and installed a new fan.

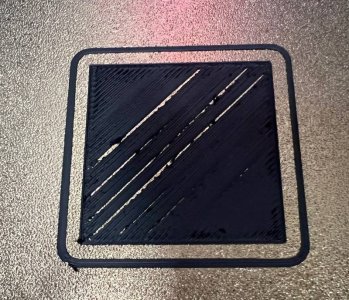

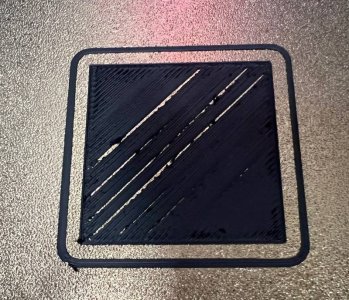

On first testing, things were looking good, but now we can print decent small parts, but the moment we try to print any surface with a longer flat layer, we get gaps in the layer.

Any suggestions?

On first testing, things were looking good, but now we can print decent small parts, but the moment we try to print any surface with a longer flat layer, we get gaps in the layer.

Any suggestions?