- Printer Model

- Trident 300mm

- Extruder Type

- Clockwork 2

- Cooling Type

- Stealthburner

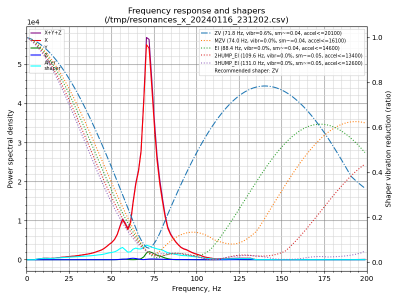

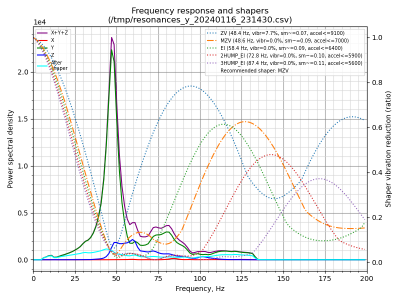

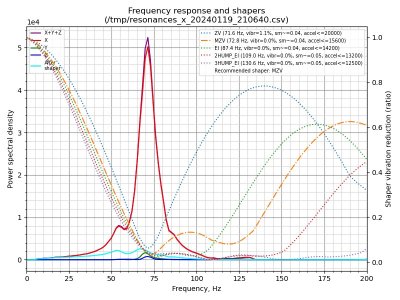

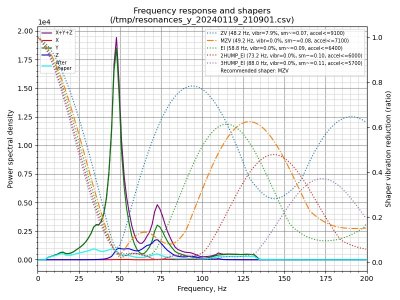

Can someone look at my attached input shaper results - been having some fun wiring a sensor up tonight and got my first measurements out of it. Seems that many are suggesting a lower resonant frequency for X (~50hz) but I'm getting over 70 - belts over-tight? I'm hitting just over 110hz when I strum them. I've de-racked as best I can (maybe not quite perfect - 1mm out on opposing corners) and I can't detect any skew in my test prints.

This is my first voron and first CoreXY printer, so I'd welcome a more experienced eye casting a glance in my direction and ask the appropriate questions

This is my first voron and first CoreXY printer, so I'd welcome a more experienced eye casting a glance in my direction and ask the appropriate questions