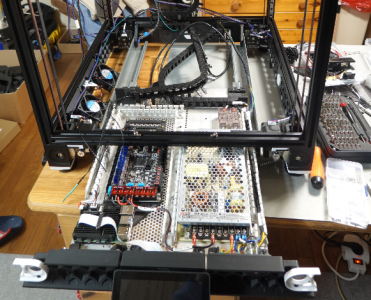

That's nothing stopping you from flipping the printer, and the inversion does nothing to the Z-Axis, so you'll be in the same situation in your hypothetical scenario. The main supply fuse is next to the plug incomer, so no need to access the bay to get there.I don't have a Trident, nor any plans to build one. What happens if the bed is halfway or more down the build volume and one or more of the Z-axis stops moving? There is no good way into the electronics bay for diagnostics and repair. A blown fuse, a failed power supply - anything that precludes moving the bed could mean a full disassembly rather than a quick tilt and repair.

My 2.4 has a remixed version of the rocknroll legs. It does require some space to tilt back, but I'm glad they are there.

I wonder why (if you don't plan to build one, and don't already have one) you would argue against it in the first place? It's hardly an option on the 2.4 due to its fixed bed, so I get why you might not even consider it. On a trident with a moving bed and space underneath, why eliminate the option?