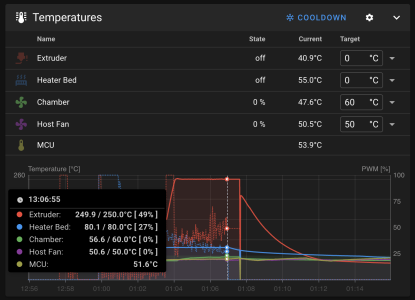

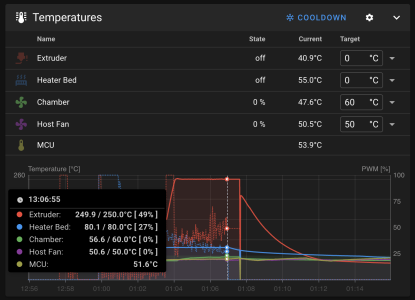

I'm experiencing a random connection issue and am seeking assistance with resolving it. I have a Voron 2.4 Formbot kit with BTT Manta M8P 2.0 + CB1 connected to EBB SB2209 CAN V1.0 (RP2040) via CAN. Randomly, during the printing, I'm getting an error "Lost communication with MCU 'EBBCan' Once the underlying issue is corrected, use the "FIRMWARE_ RESTART" command to reset the firmware, reload the config, and restart the host software. Printer is shutdown". This could happen after 3 minutes of printing, or after 30-40 minutes, or not occur during more than 1 hour of printing. After a firmware restart, everything is back to normal, and a new print can be started again right away.

What I've tried/did so far:

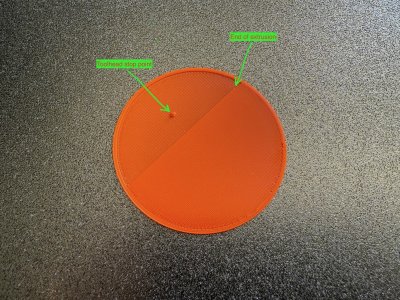

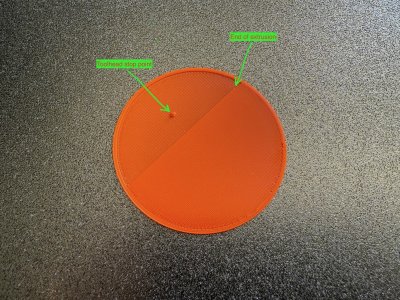

Nothing from above helped. Random disconnects continue. Another thing I noticed is that it looks like the toolhead continues moving even after the filament has already stopped extruding. The following picture demonstrates this. Another thing I noticed is that all interruptions occur during the solid infill printing.

I'm attaching logs and my assembly photo (I use a cable fastening clip "EBB SB2240_2209 CAN/CAD/Printed_Part_for_CAN_Cable_V1.2.STEP" to immobilize the connection, but it is detached in this photo).

I'm also attaching my logs. I would appreciate any help with this.

What I've tried/did so far:

- Upgraded Klipper to the latest version and reflashed the latest version of firmware everywhere.

- As was described in the GitHub issue https://github.com/bigtreetech/EBB/issues/164, I added grounding for the extruder motor.

- Unfolded the CAN cable and removed it from the case.

- Tried checking connections, detached/reattached cables.

- Disassembled and assembled the toolhead to make sure the extrusion is smooth and the filament does not get stuck.

- Verified voltage on the PCU during the print - stable 24.2V, no drops.

- Bought another EBB SB2209 CAN V1.0 (RP2040) + cable and replaced everything (board and cable one by one).

- Track the temperature of EBB. It's in operational limits and does not get higher than 60-65 degrees.

Nothing from above helped. Random disconnects continue. Another thing I noticed is that it looks like the toolhead continues moving even after the filament has already stopped extruding. The following picture demonstrates this. Another thing I noticed is that all interruptions occur during the solid infill printing.

I'm attaching logs and my assembly photo (I use a cable fastening clip "EBB SB2240_2209 CAN/CAD/Printed_Part_for_CAN_Cable_V1.2.STEP" to immobilize the connection, but it is detached in this photo).

I'm also attaching my logs. I would appreciate any help with this.