Ok so I have done my own shuriken tests, about 10 in total, and I have a few findings of my own to add. Fisrt of all, the speed that it tells you to set is not ever reached when you have set the dynamic speed for overhang to be active. The part is small and with that accel rate it never reaches more then 200 or something like that, depending on the overhang speed settings. Second finding is that if you actually switch all the dynamic speeds off, and you really print it at 500mm/s as the instructions tell you, you need a very high flow hotend. I do not know what hotend is used in this shown example but mine is a Revo Micro with standard brass 0.4 nozzle and that bottoms out at 13 mm^3/s. This is under 200 mm/s print speed if you print in a long straight line and you actually reach that speed.

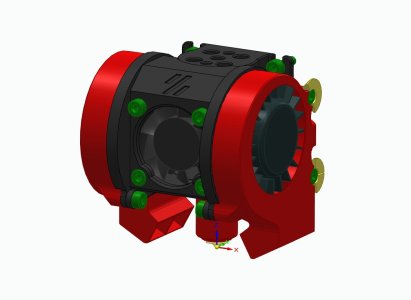

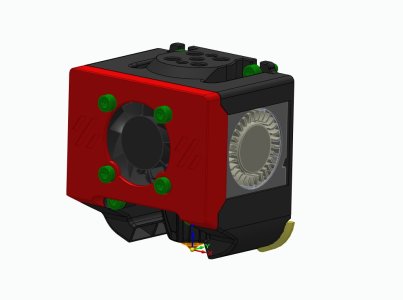

So when I set my voron 2.4/350 to 500mm/s with 10000 mm/s^3, the best speed it got on this model with dynamic overhang speed was about 200 to 250mm/s. The results were not accapetable to me. I do not want to print for speed only, my parts have to fit, perform a function and most of the time need to look at least half decent. My machine is using a 7040 cpap which cools via a modified mantis duct. Generally this is considered to be a very efficient parts cooler, most people turn the fan speed down to 60% or so for normal situations. For my test I ran it at 100% and it is very noisy, but that is not the purpose of the test.

When I run the print at 300 mm/s and dynamic overhang is set to scaling %age from 50% at 75% overhang to 10% speed at bridging, the results were near perfect with the fan running at 100% speed. The duration of my test print was somewhere around 7 minutes 20 seconds. If I want perfect I need to run at 200 mm/s with dynamics on and then it takes nearly 9 minutes.

Questions I have are:

1) what were all of your settings to get that result?

2) how long did it take the printer to print (not counting the bedlevel mesh time)

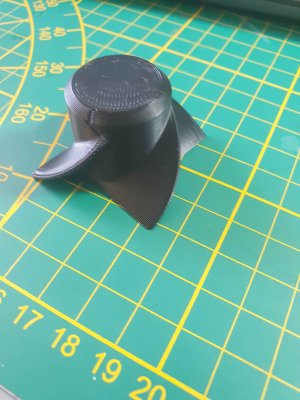

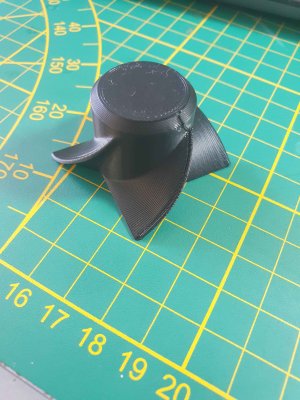

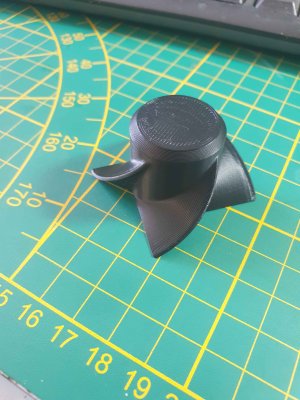

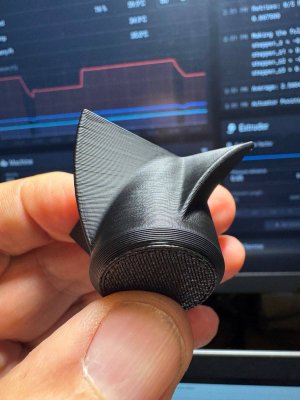

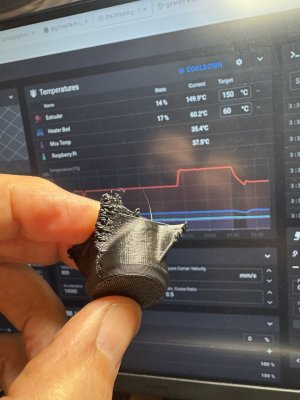

See photos of my prints attached.

Please note that the actual speed reached during printing depends massively on the slicer settings, and not only on the speed settings for perimeters and such. In the samples below the speeds are in the filename but the actual maximum speeds reached were respectively 195 for the 300, 160 for the 200 and 350 for the 500_no dynamic.

My hotend bottoms out at around 190 to 200 so my results show this fact really well. The 300 is still acceptable for most parts but do show slight under extrusion and cooling shortage, while the 200 is perfect in every way. The failed print was clearly under extruding by massive amounts. On that one I saw extrusion volumetric values of nearly 30 coming passed and this is clearly visible.

If I pursued ultra fast printing I would need to step up to a much higher flow extruder, but it is not my game to be honest. If you compare my print durations with standard out of the box machines I am 2 to 3 times faster while holding (near) perfect quality. And that is what I am after.

Setup:

RPI 4 8Gb

Octopus V1.1

LDO orbiter V2.5

Revo micro

Cpap 7040 with modified mantis duct

Looking forward to your settings so we may evaluate further.

P.S. looking at my own pictures I was reminded by that I should lower my z-offset a bit more, so please forgive me, I will do it for the next print I start

www.thingiverse.com

www.thingiverse.com

www.thingiverse.com

www.thingiverse.com