Kwadratowicz

Member

Hello there good People,

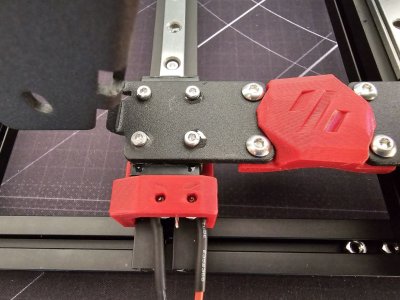

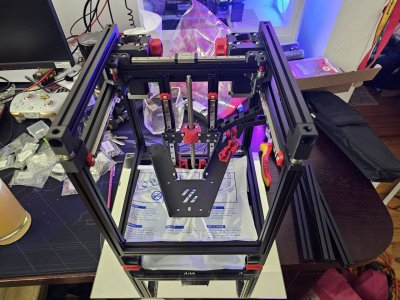

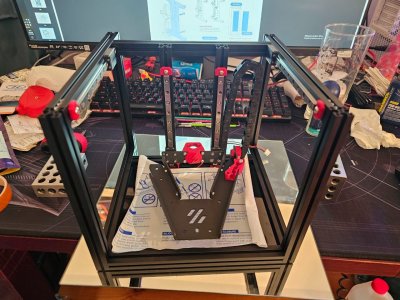

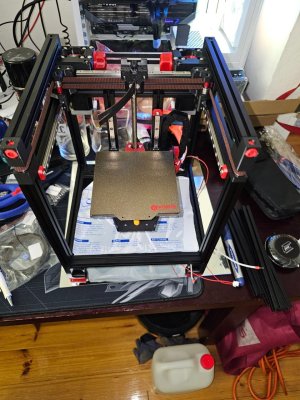

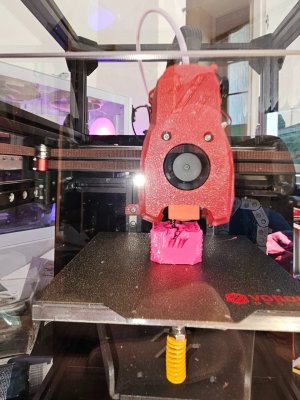

I've finally started working on voron 0.2 r1 kit from formbot.

everything is from formbot even 3d printed parts.

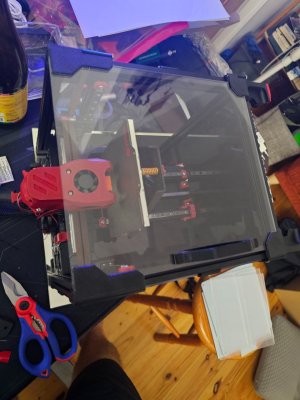

Funny thing m2 bolts are not 1.5 hex but something between 1.5 and 2. (I've tested with different stuff and finally some torx was great for it, and for now I'm using torx to fasten anything on printer).

Formbot don't have 3d printed guards for nuts, but I've got from them metal bars with threads for linear rails.

I've used ptfe lubricant, but after few days it is a little bit to tacky, but if It won't work I will see on the end of building.

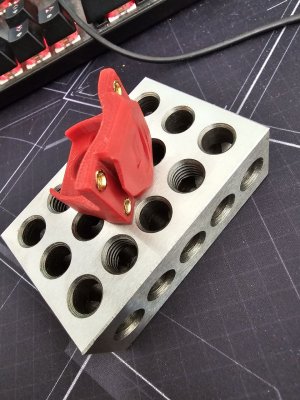

I've bought those blocks that helped Me with squared set of extrusion I've used wirehead idea of clamps and blocks (thanks )

)

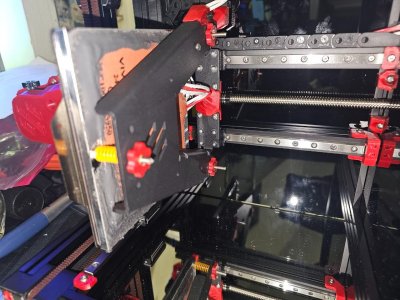

One of the linear rails was damaged by Me when I was testing lubricants, and now it is a little bit worse than the others, so it goes for the z axis.

(I've tested a few lubricants and with brake cleaner I was testing what is best for me, and unfortunately nothing that I have is great -.- )

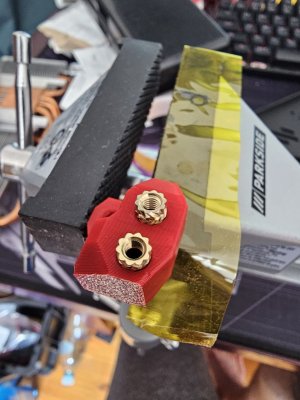

Now I'm waiting for work to end, and I will be trying My first heat inserts in life .

.

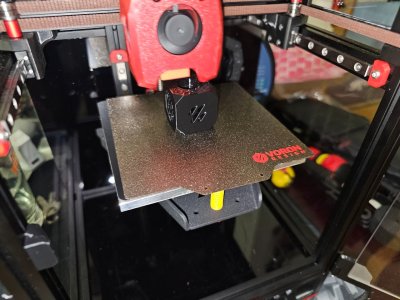

Ps the mirror is from ender 3 I think, it is only flat surface that I have and is not that big .

.

I've finally started working on voron 0.2 r1 kit from formbot.

everything is from formbot even 3d printed parts.

Funny thing m2 bolts are not 1.5 hex but something between 1.5 and 2. (I've tested with different stuff and finally some torx was great for it, and for now I'm using torx to fasten anything on printer).

Formbot don't have 3d printed guards for nuts, but I've got from them metal bars with threads for linear rails.

I've used ptfe lubricant, but after few days it is a little bit to tacky, but if It won't work I will see on the end of building.

I've bought those blocks that helped Me with squared set of extrusion I've used wirehead idea of clamps and blocks (thanks

One of the linear rails was damaged by Me when I was testing lubricants, and now it is a little bit worse than the others, so it goes for the z axis.

(I've tested a few lubricants and with brake cleaner I was testing what is best for me, and unfortunately nothing that I have is great -.- )

Now I'm waiting for work to end, and I will be trying My first heat inserts in life

Ps the mirror is from ender 3 I think, it is only flat surface that I have and is not that big