Hi, I am attempting a Voron 2.4 build and I am having some issues when it comes to printing the ABS parts. Hoping someone will have some advice for me so I can improve the printed parts quality.

Now I know that this is not ideal because a lot of things depend on filament use, the 3d printer used for printing, and of course slicer settings but I will do my best to provide information about all of these without being overly overwhelming.

I am mainly facing 3 issues when attempting to print these parts with ABS, never printed with ABS before but I never faced similar issues with any other plastic type that I tried before.

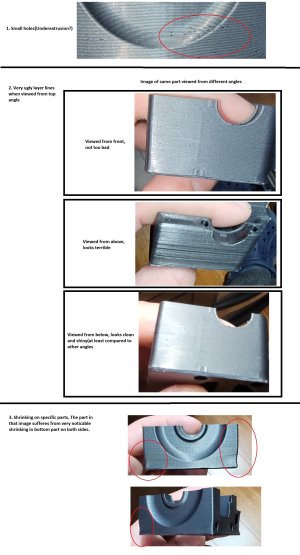

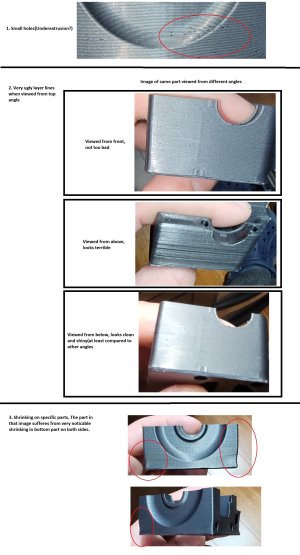

Please see attached image demonstrating all 3 of these issues.

1. Small holes throughout the surface, seems like plastic is just missing for that specific 1-2 mm

2. layer lines just look terrible when viewing the parts from above, they look relatively great from any other angle.

3. Shrinking/warping. Is this amount of shrinking still fine or this won't work? All other parts that I printed so far are much better, but this part specifically is shrinking at the bottom no matter what I tried so far.

I am printing these with a Qidi X-CF Pro, enclosed printer, 110C bed temp, 230C nozzle temp, and ambient temperature inside the printer is somewhere between 60-70C. I tried printing these both at normal speed (which is not that fast at around 60mm/s) and also slowed down and the results were pretty much the same.

Thank you.

Now I know that this is not ideal because a lot of things depend on filament use, the 3d printer used for printing, and of course slicer settings but I will do my best to provide information about all of these without being overly overwhelming.

I am mainly facing 3 issues when attempting to print these parts with ABS, never printed with ABS before but I never faced similar issues with any other plastic type that I tried before.

Please see attached image demonstrating all 3 of these issues.

1. Small holes throughout the surface, seems like plastic is just missing for that specific 1-2 mm

2. layer lines just look terrible when viewing the parts from above, they look relatively great from any other angle.

3. Shrinking/warping. Is this amount of shrinking still fine or this won't work? All other parts that I printed so far are much better, but this part specifically is shrinking at the bottom no matter what I tried so far.

I am printing these with a Qidi X-CF Pro, enclosed printer, 110C bed temp, 230C nozzle temp, and ambient temperature inside the printer is somewhere between 60-70C. I tried printing these both at normal speed (which is not that fast at around 60mm/s) and also slowed down and the results were pretty much the same.

Thank you.