Hello,

For the voron trident 300 build the configurator suggested these motors but I am able to find them locally

Can someone help me interpret the nema 17 motors for me, so I can at least pick something close to the required spec.

For the voron trident 300 build the configurator suggested these motors but I am able to find them locally

Can someone help me interpret the nema 17 motors for me, so I can at least pick something close to the required spec.

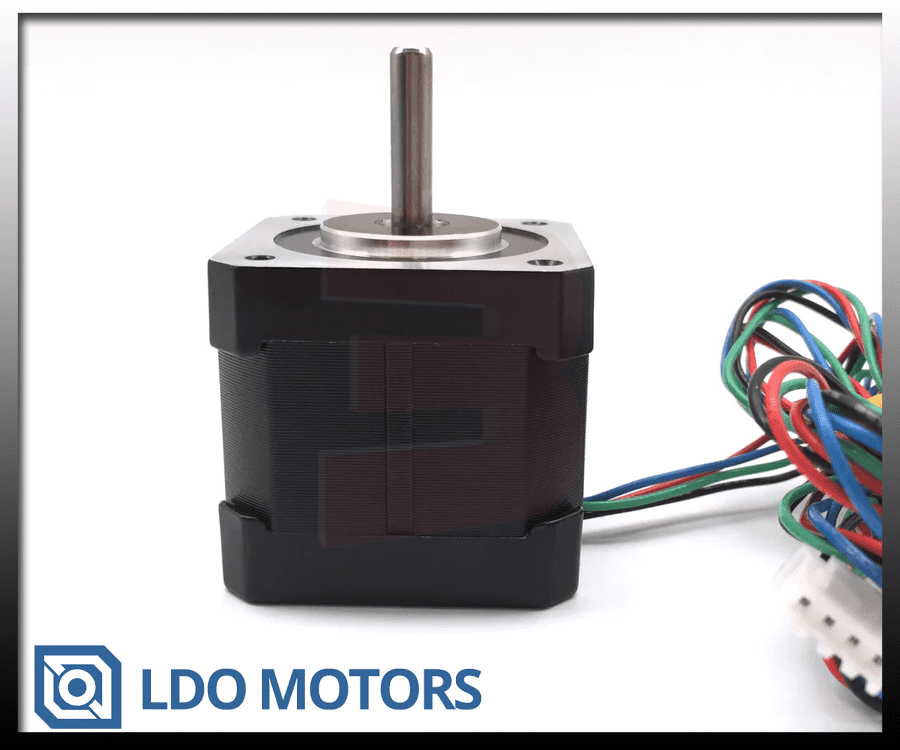

- NEMA17 TR8x8 300mm Linear Stepper

- NEMA17 Motor 17HS19-2004S

- NEMA17 Motor 17HS08-1004S