Rhoobarb2005

Member

Hi all.

Hoping someone can help a 'new to 3D printing' user out.

We've been looking at getting a 3d printer for a while. We know Creality are fairly common and we wanted the biggest print size we could reasonably afford.

So we found a used CR10 5S, where the advert stated: "Now running Klipper"

After a quick Google of what Klipper was, we thought "fair enough" and bought it. Brought it home to find that most of the cables were unplugged or disconnected, but I assumed it would be fairly simple to find where they go (Ha, that took many hours of my time up).

Well that was a couple of weeks ago because it seems that there is more to this upgraded machine than just Klipper. A lot more.

So it seems that I, as someone who has never even been in the same room as a 3d printer, have thrown myself unknowingly well into the deep end.

It has taken me a while to identify parts and boards and configuring them all, while having 0 knowledge only 2 weeks ago. It has been quite the challenge.

So what I think I have learned about the system over the last 2 weeks:

- Creality CR10 5S frame.

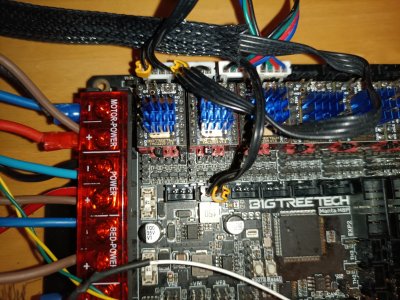

- The main board is a BTT Manta M8P v1.1

- 8x TMC2209 1.3 boards

- Controlled by a BTT CB1

- The printer itself does not have a touch display, monitor output only via HDMI

- Voron Stealthburner with a BTT SB2209 RP2040 controller

- Voron Tap

- Phaetus Dragon hotend

- 100k Ntc 3950 Thermistor

- Creality filament Endstop.

So someone has obviously spent a lot of time and money on it.

On the journey of getting this to work, I have learned a lot, but I have come to realise that when configuring there are many branching paths that you can be lead down for hours, and then finally end up in a dead end anyway and having to go back to the begining.

But I have hit a bick wall now where I don't know how to proceed. Hoping someone here can guide me.

I think I have got the printer.cfg mostly configured. The temps seem to be working. Klipper is no longer giving error messages in startup (so many errors!). The webcam display comes on, etc.

But I cannot "Home", because it says that one of the endstops is always triggered.

But when I QUERY_ENDSTOPS it says:

EndstopX TRIGGERED #Virtual Endstop

EndstopY TRIGGERED

EndstopZ TRIGGERED

Probe TRIGGERED

I seem to be going round and round in circles and am starting to pull my hair out.

I have tried adjusting the stall threshhold

I have adjusted the pin settings using for example:

endstop_pin: PC0

endstop_pin: !PC0

endstop_pin: ^PC0

endstop_pin: ^!PC0

While they do change the state, when the 1x hardware endstop is pressed to test (the LED on the switch lights up to show the change in state), the state doesnt change.

I'm sure there are more problems along the way, but this seems to be the roadblock I can't figure out.

Any help would be gratefully received.

Also as an addition, I did try to contact the owner. But the response was a waste of time, they couldn't even remember what equipment was in the printer. Their answer to me having trouble was the offer to sell me another CR10 that was modified differently to mine. From the interactions I have no doubt that there is a strong neurodivergeant issue there. No judgement, but "go back to the seller" isnt really an option at this point.

Any help anyone can provide would be fantastic.

Thanks

Hoping someone can help a 'new to 3D printing' user out.

We've been looking at getting a 3d printer for a while. We know Creality are fairly common and we wanted the biggest print size we could reasonably afford.

So we found a used CR10 5S, where the advert stated: "Now running Klipper"

After a quick Google of what Klipper was, we thought "fair enough" and bought it. Brought it home to find that most of the cables were unplugged or disconnected, but I assumed it would be fairly simple to find where they go (Ha, that took many hours of my time up).

Well that was a couple of weeks ago because it seems that there is more to this upgraded machine than just Klipper. A lot more.

So it seems that I, as someone who has never even been in the same room as a 3d printer, have thrown myself unknowingly well into the deep end.

It has taken me a while to identify parts and boards and configuring them all, while having 0 knowledge only 2 weeks ago. It has been quite the challenge.

So what I think I have learned about the system over the last 2 weeks:

- Creality CR10 5S frame.

- The main board is a BTT Manta M8P v1.1

- 8x TMC2209 1.3 boards

- Controlled by a BTT CB1

- The printer itself does not have a touch display, monitor output only via HDMI

- Voron Stealthburner with a BTT SB2209 RP2040 controller

- Voron Tap

- Phaetus Dragon hotend

- 100k Ntc 3950 Thermistor

- Creality filament Endstop.

So someone has obviously spent a lot of time and money on it.

On the journey of getting this to work, I have learned a lot, but I have come to realise that when configuring there are many branching paths that you can be lead down for hours, and then finally end up in a dead end anyway and having to go back to the begining.

But I have hit a bick wall now where I don't know how to proceed. Hoping someone here can guide me.

I think I have got the printer.cfg mostly configured. The temps seem to be working. Klipper is no longer giving error messages in startup (so many errors!). The webcam display comes on, etc.

But I cannot "Home", because it says that one of the endstops is always triggered.

But when I QUERY_ENDSTOPS it says:

EndstopX TRIGGERED #Virtual Endstop

EndstopY TRIGGERED

EndstopZ TRIGGERED

Probe TRIGGERED

I seem to be going round and round in circles and am starting to pull my hair out.

I have tried adjusting the stall threshhold

I have adjusted the pin settings using for example:

endstop_pin: PC0

endstop_pin: !PC0

endstop_pin: ^PC0

endstop_pin: ^!PC0

While they do change the state, when the 1x hardware endstop is pressed to test (the LED on the switch lights up to show the change in state), the state doesnt change.

I'm sure there are more problems along the way, but this seems to be the roadblock I can't figure out.

Any help would be gratefully received.

Also as an addition, I did try to contact the owner. But the response was a waste of time, they couldn't even remember what equipment was in the printer. Their answer to me having trouble was the offer to sell me another CR10 that was modified differently to mine. From the interactions I have no doubt that there is a strong neurodivergeant issue there. No judgement, but "go back to the seller" isnt really an option at this point.

Any help anyone can provide would be fantastic.

Thanks