I have just setup Octoprint on Klipper with Octoprint V1.1 with the CAN Bridge to EBB36 V1.2 CAN toolhead

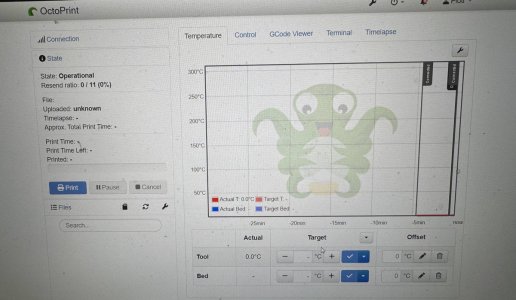

Everything has worked fine the first time. the temps showed right temps and were changing as they should

Im not sure what happened.

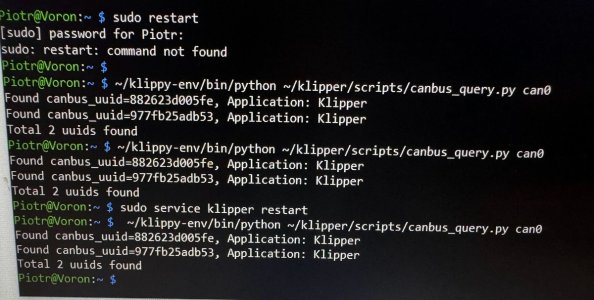

When I run ~/klippy-env/bin/python ~/klipper/scripts/canbus_query.py can0 both the Ectopus and EBB36 show up on the networj with correct id

Can anybody point me to the right direction?

Here is my printer.cfg

# This file contains common pin mappings for the BigTreeTech Octopus

# (non-Pro) boards.

# Important! Do not use this config with an Octopus Pro v1.1 board as

# doing so could result in a heater being inadvertently enabled.

# To use this config, start by identifying the micro-controller on the

# board - it may be an STM32F446, or STM32F429. Select the

# appropriate micro-controller in "make menuconfig" and select "Enable

# low-level configuration options". For STM32F446 boards the firmware

# should be compiled with a "32KiB bootloader" and a "12MHz crystal"

# clock reference. For STM32F429 boards use a "32KiB bootloader" and

# an "8MHz crystal".

# See docs/Config_Reference.md for a description of parameters.

# Driver0

[stepper_x]

step_pin: PF13

dir_pin: PF12

enable_pin: !PF14

microsteps: 16

rotation_distance: 40

endstop_pin: EBBCan B6

B6

position_endstop: 0

position_max: 200

homing_speed: 50

# Driver1

[stepper_y]

step_pin: PG0

dir_pin: PG1

enable_pin: !PF15

microsteps: 16

rotation_distance: 40

endstop_pin: PG9

position_endstop: 0

position_max: 200

homing_speed: 50

# Driver2

[stepper_z]

step_pin: PF11

dir_pin: PG3

enable_pin: !PG5

microsteps: 16

rotation_distance: 8

endstop_pin: PG10

position_endstop: 0.5

position_max: 200

# Driver3

# The Octopus only has 4 heater outputs which leaves an extra stepper

# This can be used for a second Z stepper, dual_carriage, extruder co-stepper,

# or other accesory such as an MMU

#[stepper_]

#step_pin: PG4

#dir_pin: PC1

#enable_pin: !PA0

#endstop_pin: PG11

#...

# Driver4

[extruder]

step_pin: EBBCan D0

D0

dir_pin: !EBBCan D1

D1

enable_pin: !EBBCan D2

D2

microsteps: 16

rotation_distance: 33.500

nozzle_diameter: 0.400

filament_diameter: 1.750

heater_pin: EBBCan: PB13

sensor_pin: EBBCan: PA3

sensor_type: ATC Semitec 104NT-4-R025H42G

control: pid

pid_Kp: 22.2

pid_Ki: 1.08

pid_Kd: 114

min_temp: 0

max_temp: 250

#[filament_switch_sensor material_0]

#switch_pin: PG12

# Driver5

#[extruder1]

#step_pin: PC13

#dir_pin: PF0

#enable_pin: !PF1

#heater_pin: PA3 # HE1

#sensor_pin: PF5 # T1

#...

#[filament_switch_sensor material_1]

#switch_pin: PG13

# Driver6

#[extruder2]

#step_pin: PE2

#dir_pin: PE3

#enable_pin: !PD4

#heater_pin: PB10 # HE2

#sensor_pin: PF6 # T2

#...

#[filament_switch_sensor material_2]

#switch_pin: PG14

# Driver7

#[extruder3]

#step_pin: PE6

#dir_pin: PA14

#enable_pin: !PE0

#heater_pin: PB11 # HE3

#sensor_pin: PF7 # T3

#...

#[filament_switch_sensor material_3]

#switch_pin: PG15

[heater_bed]

heater_pin: PA1

sensor_pin: PF3 # TB

sensor_type: Generic 3950

control: watermark

min_temp: 0

max_temp: 130

[Cooling Fan0]

pin: EBBCan: PA1

#[Hot End Fan fan1]

pin: EBBCan A0

A0

#[heater_fan fan2]

#pin: PA1

#[heater_fan fan3]

#pin: PD13

#[heater_fan fan4]

#pin: PD14

#[controller_fan fan5]

#pin: PD15

### mcu settings #####################################

[mcu]

canbus_uuid: 882623d005fe

[mcu EBBCan]

canbus_uuid: 977fb25adb53

[printer]

kinematics: cartesian

max_velocity: 300

max_accel: 3000

max_z_velocity: 5

max_z_accel: 100

########################################

# TMC2209 configuration

########################################

#[tmc2209 stepper_x]

#uart_pin: PC4

##diag_pin: PG6

#run_current: 0.800

#stealthchop_threshold: 999999

#[tmc2209 stepper_y]

#uart_pin: PD11

##diag_pin: PG9

#run_current: 0.800

#stealthchop_threshold: 999999

#[tmc2209 stepper_z]

#uart_pin: PC6

##diag_pin: PG10

#run_current: 0.650

#stealthchop_threshold: 999999

#[tmc2209 stepper_]

#uart_pin: PC7

##diag_pin: PG11

#run_current: 0.650

#stealthchop_threshold: 999999

#[tmc2209 extruder]

#uart_pin: EBBCan: PA15

#run_current: 0.800

#stealthchop_threshold: 999999

#[tmc2209 extruder1]

#uart_pin: PE4

#run_current: 0.800

#stealthchop_threshold: 999999

#[tmc2209 extruder2]

#uart_pin: PE1

#run_current: 0.800

#stealthchop_threshold: 999999

#[tmc2209 extruder3]

#uart_pin: PD3

#run_current: 0.800

#stealthchop_threshold: 999999

########################################

# TMC2130 configuration

########################################

#[tmc2130 stepper_x]

#cs_pin: PC4

#spi_bus: spi1

##diag1_pin: PG6

#run_current: 0.800

#stealthchop_threshold: 999999

#[tmc2130 stepper_y]

#cs_pin: PD11

#spi_bus: spi1

##diag1_pin: PG9

#run_current: 0.800

#stealthchop_threshold: 999999

#[tmc2130 stepper_z]

#cs_pin: PC6

#spi_bus: spi1

##diag1_pin: PG10

#run_current: 0.650

#stealthchop_threshold: 999999

#[tmc2130 stepper_]

#cs_pin: PC7

#spi_bus: spi1

##diag1_pin: PG11

#run_current: 0.800

#stealthchop_threshold: 999999

#[tmc2130 extruder]

#cs_pin: PF2

#spi_bus: spi1

#run_current: 0.800

#stealthchop_threshold: 999999

#[tmc2130 extruder1]

#cs_pin: PE4

#spi_bus: spi1

#run_current: 0.800

#stealthchop_threshold: 999999

#[tmc2130 extruder2]

#cs_pin: PE1

#spi_bus: spi1

#run_current: 0.800

#stealthchop_threshold: 999999

#[tmc2130 extruder3]

#cs_pin: PD3

#spi_bus: spi1

#run_current: 0.800

#stealthchop_threshold: 999999

[board_pins]

aliases:

# EXP1 header

EXP1_1=PE8, EXP1_2=PE7,

EXP1_3=PE9, EXP1_4=PE10,

EXP1_5=PE12, EXP1_6=PE13, # Slot in the socket on this side

EXP1_7=PE14, EXP1_8=PE15,

EXP1_9=<GND>, EXP1_10=<5V>,

# EXP2 header

EXP2_1=PA6, EXP2_2=PA5,

EXP2_3=PB1, EXP2_4=PA4,

EXP2_5=PB2, EXP2_6=PA7, # Slot in the socket on this side

EXP2_7=PC15, EXP2_8=<RST>,

EXP2_9=<GND>, EXP2_10=PC5

# See the sample-lcd.cfg file for definitions of common LCD displays.

# A [probe] section can be defined instead with a pin: setting identical

# to the sensor_pin: for a bltouch

#[bltouch]

#sensor_pin: PB7

#control_pin: PB6

#z_offset: 0

[neopixel sb_leds]

pin: EBBCan D3

D3

[temperature_sensor EBBCan]

sensor_type: temperature_mcu

sensor_mcu: EBBCan

min_temp: 0

max_temp: 100

[adxl345]

cs_pin: EBBCan B12

B12

spi_software_sclk_pin: EBBCan B10

B10

spi_software_mosi_pin: EBBCan B11

B11

spi_software_miso_pin: EBBCan B2

B2

axes_map: x,y,z

[resonance_tester]

accel_chip: adxl345

probe_points: 175,175,20

Everything has worked fine the first time. the temps showed right temps and were changing as they should

Im not sure what happened.

When I run ~/klippy-env/bin/python ~/klipper/scripts/canbus_query.py can0 both the Ectopus and EBB36 show up on the networj with correct id

Can anybody point me to the right direction?

Here is my printer.cfg

# This file contains common pin mappings for the BigTreeTech Octopus

# (non-Pro) boards.

# Important! Do not use this config with an Octopus Pro v1.1 board as

# doing so could result in a heater being inadvertently enabled.

# To use this config, start by identifying the micro-controller on the

# board - it may be an STM32F446, or STM32F429. Select the

# appropriate micro-controller in "make menuconfig" and select "Enable

# low-level configuration options". For STM32F446 boards the firmware

# should be compiled with a "32KiB bootloader" and a "12MHz crystal"

# clock reference. For STM32F429 boards use a "32KiB bootloader" and

# an "8MHz crystal".

# See docs/Config_Reference.md for a description of parameters.

# Driver0

[stepper_x]

step_pin: PF13

dir_pin: PF12

enable_pin: !PF14

microsteps: 16

rotation_distance: 40

endstop_pin: EBBCan

position_endstop: 0

position_max: 200

homing_speed: 50

# Driver1

[stepper_y]

step_pin: PG0

dir_pin: PG1

enable_pin: !PF15

microsteps: 16

rotation_distance: 40

endstop_pin: PG9

position_endstop: 0

position_max: 200

homing_speed: 50

# Driver2

[stepper_z]

step_pin: PF11

dir_pin: PG3

enable_pin: !PG5

microsteps: 16

rotation_distance: 8

endstop_pin: PG10

position_endstop: 0.5

position_max: 200

# Driver3

# The Octopus only has 4 heater outputs which leaves an extra stepper

# This can be used for a second Z stepper, dual_carriage, extruder co-stepper,

# or other accesory such as an MMU

#[stepper_]

#step_pin: PG4

#dir_pin: PC1

#enable_pin: !PA0

#endstop_pin: PG11

#...

# Driver4

[extruder]

step_pin: EBBCan

dir_pin: !EBBCan

enable_pin: !EBBCan

microsteps: 16

rotation_distance: 33.500

nozzle_diameter: 0.400

filament_diameter: 1.750

heater_pin: EBBCan: PB13

sensor_pin: EBBCan: PA3

sensor_type: ATC Semitec 104NT-4-R025H42G

control: pid

pid_Kp: 22.2

pid_Ki: 1.08

pid_Kd: 114

min_temp: 0

max_temp: 250

#[filament_switch_sensor material_0]

#switch_pin: PG12

# Driver5

#[extruder1]

#step_pin: PC13

#dir_pin: PF0

#enable_pin: !PF1

#heater_pin: PA3 # HE1

#sensor_pin: PF5 # T1

#...

#[filament_switch_sensor material_1]

#switch_pin: PG13

# Driver6

#[extruder2]

#step_pin: PE2

#dir_pin: PE3

#enable_pin: !PD4

#heater_pin: PB10 # HE2

#sensor_pin: PF6 # T2

#...

#[filament_switch_sensor material_2]

#switch_pin: PG14

# Driver7

#[extruder3]

#step_pin: PE6

#dir_pin: PA14

#enable_pin: !PE0

#heater_pin: PB11 # HE3

#sensor_pin: PF7 # T3

#...

#[filament_switch_sensor material_3]

#switch_pin: PG15

[heater_bed]

heater_pin: PA1

sensor_pin: PF3 # TB

sensor_type: Generic 3950

control: watermark

min_temp: 0

max_temp: 130

[Cooling Fan0]

pin: EBBCan: PA1

#[Hot End Fan fan1]

pin: EBBCan

#[heater_fan fan2]

#pin: PA1

#[heater_fan fan3]

#pin: PD13

#[heater_fan fan4]

#pin: PD14

#[controller_fan fan5]

#pin: PD15

### mcu settings #####################################

[mcu]

canbus_uuid: 882623d005fe

[mcu EBBCan]

canbus_uuid: 977fb25adb53

[printer]

kinematics: cartesian

max_velocity: 300

max_accel: 3000

max_z_velocity: 5

max_z_accel: 100

########################################

# TMC2209 configuration

########################################

#[tmc2209 stepper_x]

#uart_pin: PC4

##diag_pin: PG6

#run_current: 0.800

#stealthchop_threshold: 999999

#[tmc2209 stepper_y]

#uart_pin: PD11

##diag_pin: PG9

#run_current: 0.800

#stealthchop_threshold: 999999

#[tmc2209 stepper_z]

#uart_pin: PC6

##diag_pin: PG10

#run_current: 0.650

#stealthchop_threshold: 999999

#[tmc2209 stepper_]

#uart_pin: PC7

##diag_pin: PG11

#run_current: 0.650

#stealthchop_threshold: 999999

#[tmc2209 extruder]

#uart_pin: EBBCan: PA15

#run_current: 0.800

#stealthchop_threshold: 999999

#[tmc2209 extruder1]

#uart_pin: PE4

#run_current: 0.800

#stealthchop_threshold: 999999

#[tmc2209 extruder2]

#uart_pin: PE1

#run_current: 0.800

#stealthchop_threshold: 999999

#[tmc2209 extruder3]

#uart_pin: PD3

#run_current: 0.800

#stealthchop_threshold: 999999

########################################

# TMC2130 configuration

########################################

#[tmc2130 stepper_x]

#cs_pin: PC4

#spi_bus: spi1

##diag1_pin: PG6

#run_current: 0.800

#stealthchop_threshold: 999999

#[tmc2130 stepper_y]

#cs_pin: PD11

#spi_bus: spi1

##diag1_pin: PG9

#run_current: 0.800

#stealthchop_threshold: 999999

#[tmc2130 stepper_z]

#cs_pin: PC6

#spi_bus: spi1

##diag1_pin: PG10

#run_current: 0.650

#stealthchop_threshold: 999999

#[tmc2130 stepper_]

#cs_pin: PC7

#spi_bus: spi1

##diag1_pin: PG11

#run_current: 0.800

#stealthchop_threshold: 999999

#[tmc2130 extruder]

#cs_pin: PF2

#spi_bus: spi1

#run_current: 0.800

#stealthchop_threshold: 999999

#[tmc2130 extruder1]

#cs_pin: PE4

#spi_bus: spi1

#run_current: 0.800

#stealthchop_threshold: 999999

#[tmc2130 extruder2]

#cs_pin: PE1

#spi_bus: spi1

#run_current: 0.800

#stealthchop_threshold: 999999

#[tmc2130 extruder3]

#cs_pin: PD3

#spi_bus: spi1

#run_current: 0.800

#stealthchop_threshold: 999999

[board_pins]

aliases:

# EXP1 header

EXP1_1=PE8, EXP1_2=PE7,

EXP1_3=PE9, EXP1_4=PE10,

EXP1_5=PE12, EXP1_6=PE13, # Slot in the socket on this side

EXP1_7=PE14, EXP1_8=PE15,

EXP1_9=<GND>, EXP1_10=<5V>,

# EXP2 header

EXP2_1=PA6, EXP2_2=PA5,

EXP2_3=PB1, EXP2_4=PA4,

EXP2_5=PB2, EXP2_6=PA7, # Slot in the socket on this side

EXP2_7=PC15, EXP2_8=<RST>,

EXP2_9=<GND>, EXP2_10=PC5

# See the sample-lcd.cfg file for definitions of common LCD displays.

# A [probe] section can be defined instead with a pin: setting identical

# to the sensor_pin: for a bltouch

#[bltouch]

#sensor_pin: PB7

#control_pin: PB6

#z_offset: 0

[neopixel sb_leds]

pin: EBBCan

[temperature_sensor EBBCan]

sensor_type: temperature_mcu

sensor_mcu: EBBCan

min_temp: 0

max_temp: 100

[adxl345]

cs_pin: EBBCan

spi_software_sclk_pin: EBBCan

spi_software_mosi_pin: EBBCan

spi_software_miso_pin: EBBCan

axes_map: x,y,z

[resonance_tester]

accel_chip: adxl345

probe_points: 175,175,20