Hi,

Busy week, thanks for getting back to me.

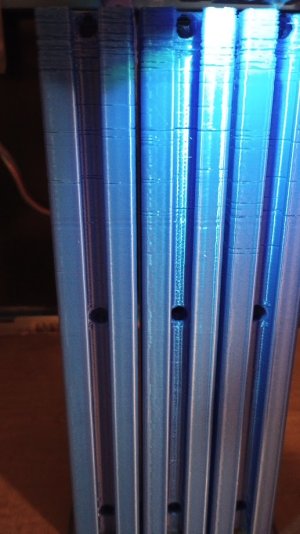

Looks like a clog or under extrusion.

New or old nozzle?

Is the filament in good shape?

Same old nozzle. 93% flow rate

Filament is a few months old.

I'm betting that if I used any other filament, I'd get the same behavior, as this used to happen at lower heights. Since then, I've deracked and haven't noticed the issue, but this is a pretty tall print.

What printer are you using?

This looks like it may be heat creep starting to kick in. Don’t take that as definitive, but just a possibility.

Another possibility of it’s a 2.4 is a change to the filament path causing more restriction. I don’t like this one but don’t want to rule it out.

If this is the first time that you’ve seen it, it may be a good, old fashioned nozzle clog.

Voron 2.4 350

Stealthburner with Phateus Rapido Hf

looking at the tube feed at this height, I could see how the pay may be obstructed.

Also, I took the side panels off, and it's been pretty cold in my garage, but the heat from the bed in combination with the extruder could be creating an area with heat trapped at the top of the printer, I guess.

I never did any extensive thermodynamics work, so not sure about that...

I'll heat the printer up and see what extrusion looks like at this height, for what it's worth.

There definitely was a delay in the initial extrusion. that may be normal, it's been a week since i've last fired her up.

BUT the tubing definitely was jerking and even squirming... so that may have been the problem?

So, the line also got thinner, after extruding 25mm @ 2mm/s. Nice fat and smooth line at first that turned into something thread-like and rough.

I've just checked the filament path after lowering the toolhead and noticing the same problem. There's what seems to be like an insane amount of resistance, but it could just be my head playing games...

Having a look... I've found a "wave" in the line of filament. something must have been going on with the roll. It's extruding as expected now...

checking again at the height that I was having problems with...

She's flowing again!!! I guess I have to be careful with my feed, inspect my rolls more carefully and watch for jerks in the line.

Thanks for the suggestions you two!!!