- Printer Model

- Trident 350

- Extruder Type

- Clockwork 2

- Cooling Type

- Stealthburner

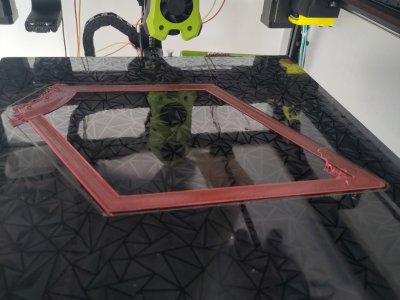

Have around 300h on my trident I think and basically, it was good so far when I print something small in the center.

If it's something big though or trying to print full plate - usually there is some high-level pitch sound occurs and leads to skipping.

Happens at random moments, on the current model for example at the beginning of the print. When it was oriented differently was happening at the end, was able to print 6 of those parts successfully actually but throw away may be another 6 that were ruined by skipping. Currently, it happens with TPU but had the same experience with full plate printing ABS parts at the very end of print.

Any help is appreciated I'm a bit out of ideas.

Or could it be smth else? Maybe smb had a similar experience?

Steppers are only lukewarm during active printing so shouldn't be an overheating issue.

My other idea was that the nozzle could hit some defects on print. but it seems that there's no serious defects when I abort the print and surely even if there are small bumps that shouldn't be an issue for a hot nozzle to pass through.

Was able to catch 2 incidents on my gopro camera, can't figure from videos much myself though.

If it's something big though or trying to print full plate - usually there is some high-level pitch sound occurs and leads to skipping.

Happens at random moments, on the current model for example at the beginning of the print. When it was oriented differently was happening at the end, was able to print 6 of those parts successfully actually but throw away may be another 6 that were ruined by skipping. Currently, it happens with TPU but had the same experience with full plate printing ABS parts at the very end of print.

Any help is appreciated I'm a bit out of ideas.

- Tried checking the screws on X and Y motors pulleys - I used a thread locker and they are still dead solid there.

- Tried tensioning belts better - now the sounds occur even earlier in the print it seems.

- Stealthchop is not enabled.

- Giving a higher current to the motors didn't help

- Using almost default OrcaSlicer profile for Voron Trident with max volumetric speed limited to 8mm/s (HF TPU)

- Checked belt paths, seem to be all as supposed to be, don't see any wear and tear on the belts.

- Using klicky with auto Z calibration and first layers look perfect or almost perfect

Or could it be smth else? Maybe smb had a similar experience?

Steppers are only lukewarm during active printing so shouldn't be an overheating issue.

My other idea was that the nozzle could hit some defects on print. but it seems that there's no serious defects when I abort the print and surely even if there are small bumps that shouldn't be an issue for a hot nozzle to pass through.

Was able to catch 2 incidents on my gopro camera, can't figure from videos much myself though.