Dutchronnie

Well-known member

I am printing parts for the voron 2.4 on my modded creality cr-10

The parts are printed with eSUN ABS+

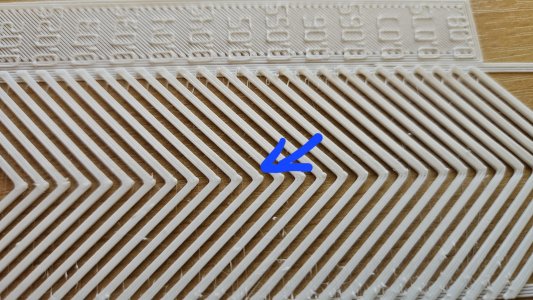

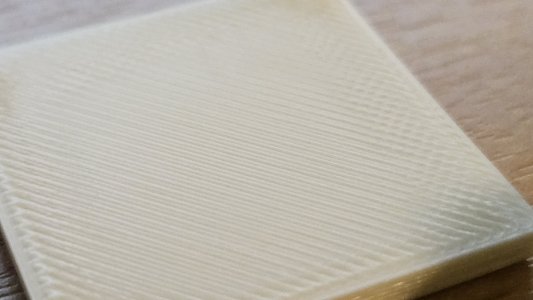

But the last layer is a littebit rough, i need to sand them to get a perfect fit. I think this can be better, i don't have this when i print PLA, only ABS

I slice the parts in Cura and print them with a temperature of 235 degrees and a bed temperature of 100 degrees.

Does somebody know how i get a smooth toplayer?

What do i have to change in Cura?

The parts are printed with eSUN ABS+

But the last layer is a littebit rough, i need to sand them to get a perfect fit. I think this can be better, i don't have this when i print PLA, only ABS

I slice the parts in Cura and print them with a temperature of 235 degrees and a bed temperature of 100 degrees.

Does somebody know how i get a smooth toplayer?

What do i have to change in Cura?