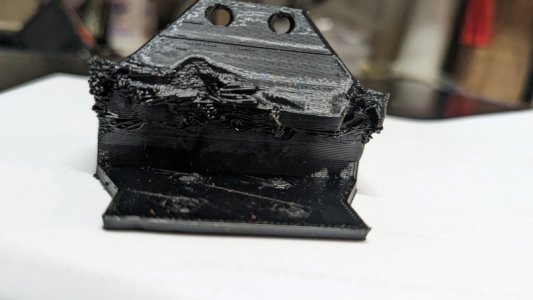

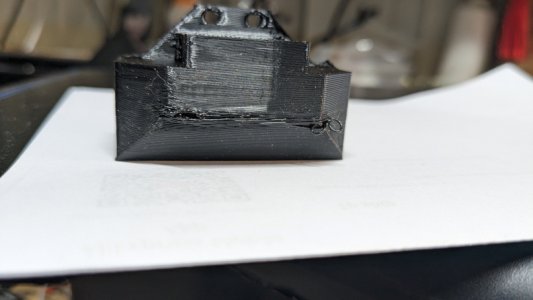

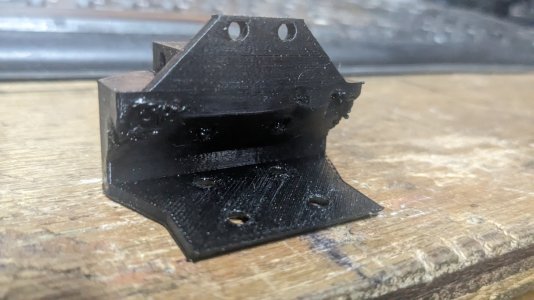

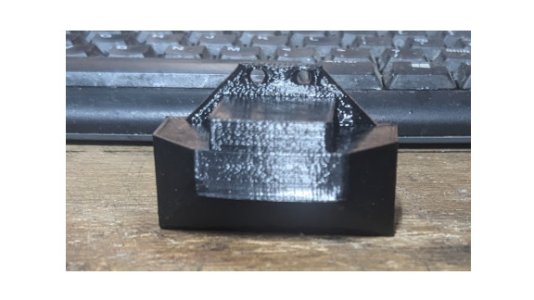

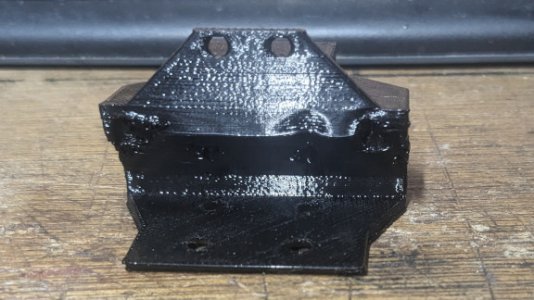

I am having a major issue with TPU. The first 30 layers are OK but then the next 70 or so are rubbish and the print is ruined, after that it prints perfectly for the rest of the job. I have tried different` levels of cooling but no difference. I don't understand why it can be good, bad and then good again with no change in settings or environment. If it was progressively getting worse then it could be cooling etc but why does it come good again. This is reproducible on every print. Any print up to about 30 layers is perfect. I print 98 shore TPU at 230, 50 and 70% fan with doors open. The hotend is an Afterburner, Clockwork 2 with Rapido and 0.4mm nozzle. Sub 30 layer prints come out perfect with no blobs or stringing. ABS(30% fan, doors closed and 50C chamber) and PLA(100% fan doors open) print perfectly and are consistent over any height. Any help would be appreciated.

VORON Design

Register a free account today to become a member! Once signed in, you'll be able to participate on this site by adding your own topics and posts, as well as connect with other members!

Question TPU issues

- Thread starter triafgg@

- Start date