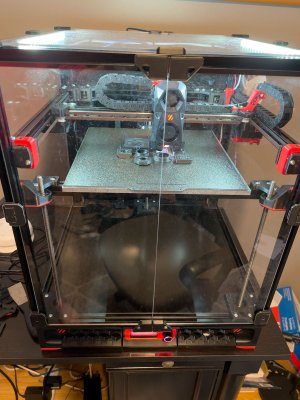

- Printer Model

- Voron Trident 300

- Cooling Type

- Stealthburner

Hi Everyone,

coming from a Ender 3 S1 Pro (almost 9 months usage). Completely new to building Vorons but have been reading and watching stuff to educate myself on building one.

Planning on a Voron Trident 300x300x250 with stealth burner using BTT SB using CAN , BTT Knomi v2.0 Touch support. Want to keep the idea open for a Tridex upgrade if possible on this machine.

Right now I am struggling to understand a few thing and have these questions.

1. Can I use a Raspberry Pi 3 Model B+ or do I need a Pi 4 ?

5. which BTT EBB SB variant to pick and what are the differences , also does this choice base on what stepper drivers I pick ?

6. if I pick the BTT Octopus Max EZ then

7. Also I decided to pick the octopus series over manta series as I want to keep my Pi separate and not mount it on the controller board

any help is really appreciated.

thank you.

coming from a Ender 3 S1 Pro (almost 9 months usage). Completely new to building Vorons but have been reading and watching stuff to educate myself on building one.

Planning on a Voron Trident 300x300x250 with stealth burner using BTT SB using CAN , BTT Knomi v2.0 Touch support. Want to keep the idea open for a Tridex upgrade if possible on this machine.

Right now I am struggling to understand a few thing and have these questions.

1. Can I use a Raspberry Pi 3 Model B+ or do I need a Pi 4 ?

- the reason I prefer the Pi 3 Model B+ is I wont need a heatsink to cool.

- I have a Pi 4 and heats up a lot where as my Pi 3 Model B runs for hours without any active cooling or heatsink

- Octopus Pro v1.0 STM32F446ZE

- Octopus Pro v1.1 STM32H723ZE

- Octopus Max EZ STM32H723ZET6

- the H723 is faster compared to F446

- are EZ slots for steppers a better design and thermal dissipation compared to traditional pin based steppers ?

- TMC2209

- TMC2208 UART

- TMC5160T Pro

- is it just that one supports more voltage range over the other

- I am just lost here what is the benefit of one above the other and what to pick here

5. which BTT EBB SB variant to pick and what are the differences , also does this choice base on what stepper drivers I pick ?

- EBB SB2209

- EBB SB2240

- EBB SB2209 CAN V1.0(RP2040)

6. if I pick the BTT Octopus Max EZ then

- do I get to skip BTT U2C v2.1 CAN Adapter

- can I directly connect the CAN based stealth burner hardware directly with BTT Max EZ

7. Also I decided to pick the octopus series over manta series as I want to keep my Pi separate and not mount it on the controller board

- Is the btt octopus pro / max ez a better board compared to btt manta m8p series

- clicky probe

- voron tap , which iteration of the design to pick.

- something else

any help is really appreciated.

thank you.

Last edited: