- Printer Model

- Trident 300mm

- Extruder Type

- Clockwork 2

- Cooling Type

- Stealthburner

Hi there,

I've just finished my Trident Build& have done a few hours of printing now, about 45h, not even done with all the "cosmetics" like Skirts etc. So also no Cerials for me....

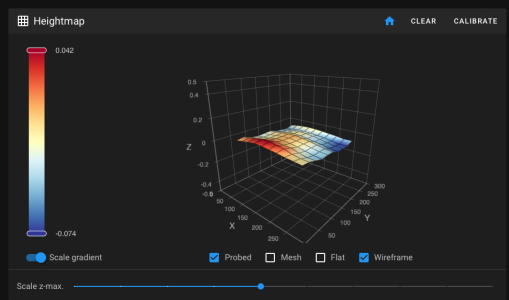

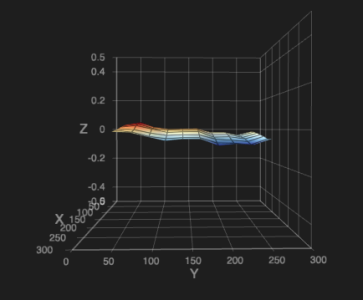

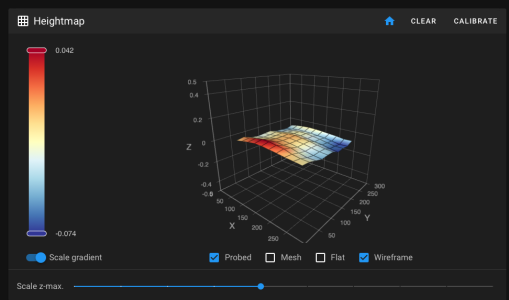

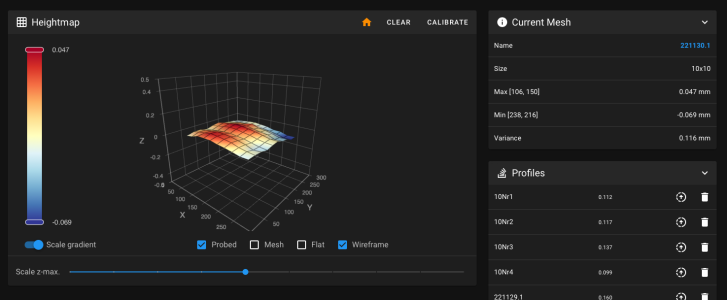

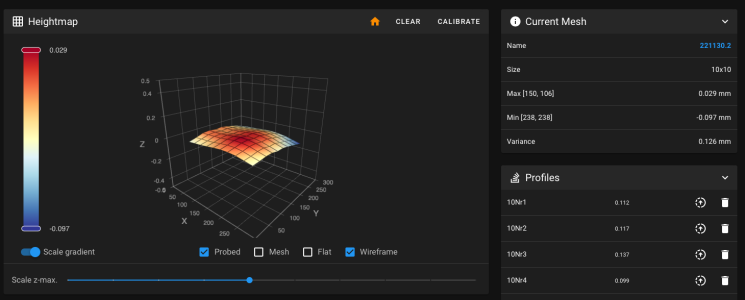

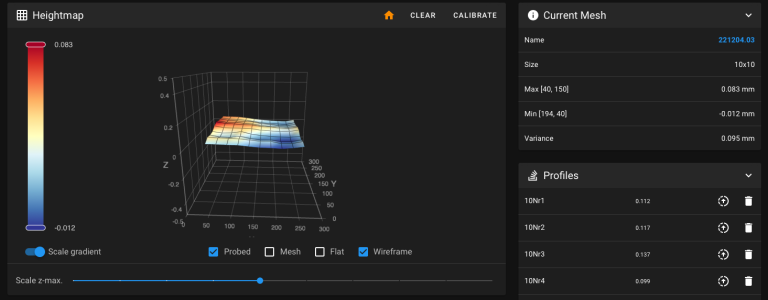

Sadly I'm relatively unhappy with the flatness of my mesh.

About my Setup:

Trident 300mm

Probe: Super Pinda aka P&F NBN 2,5-8GM35-E1-Y

Aluminum Bed: Flatness less than 0,2mm/m

I firstly used the trick from the discord to just fine tune Y extrusions and that surely helped, but there is still about 1/10 error around the surface. The Thing, that is the most important to me is the "Bow" on the X Plane.

Looks like problem on the extrusion or rail.

I rotated my Rail already 90° (so the side from the rail is now used for the cable chain and so on)

Sadly that didn't helped, I'm now thinking about flipping the Extrusion upside down, to look if the Bow just turns the other way round.

Whats your thaugts about?

Do you guys had similar issues?

Please don't start any "Mesh can compensate" posts.

I want to create a solid base model, so compensation has less to do.

Better base results in better Results, I think that's something we all should be fine with.

Sorry my bad English, but I prefer a Forum over some Discord Posts, cause I don't always have like 6h to read all messages before something "Disappears"

Regards

X11-35/2 aka Tjard

[gonna add mesh later, sadly forget to do a save config last time]

I've just finished my Trident Build& have done a few hours of printing now, about 45h, not even done with all the "cosmetics" like Skirts etc. So also no Cerials for me....

Sadly I'm relatively unhappy with the flatness of my mesh.

About my Setup:

Trident 300mm

Probe: Super Pinda aka P&F NBN 2,5-8GM35-E1-Y

Aluminum Bed: Flatness less than 0,2mm/m

I firstly used the trick from the discord to just fine tune Y extrusions and that surely helped, but there is still about 1/10 error around the surface. The Thing, that is the most important to me is the "Bow" on the X Plane.

Looks like problem on the extrusion or rail.

I rotated my Rail already 90° (so the side from the rail is now used for the cable chain and so on)

Sadly that didn't helped, I'm now thinking about flipping the Extrusion upside down, to look if the Bow just turns the other way round.

Whats your thaugts about?

Do you guys had similar issues?

Please don't start any "Mesh can compensate" posts.

I want to create a solid base model, so compensation has less to do.

Better base results in better Results, I think that's something we all should be fine with.

Sorry my bad English, but I prefer a Forum over some Discord Posts, cause I don't always have like 6h to read all messages before something "Disappears"

Regards

X11-35/2 aka Tjard

[gonna add mesh later, sadly forget to do a save config last time]

Last edited: