m00dawg

Well-known member

- Printer Model

- Trident 300

- Extruder Type

- Orbiter

- Cooling Type

- Other

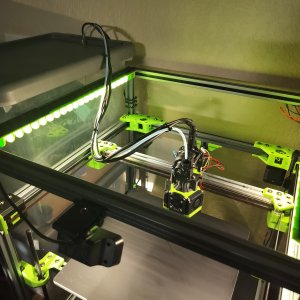

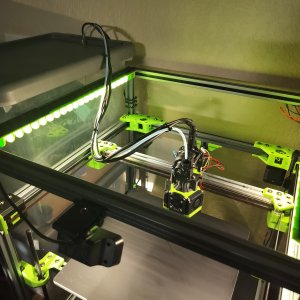

Recently I decided to try XOL/OB2. One thing I didn't realize is that it was meant for an umbilical setup so after a few other gotchas, I've been quite happy with it! I know I can improve things more though and was curious what folks are using with XOL/OB2/NH36 (with umbilical guide).

I've been happy enough with the setup but it is a little janky. I did buy some piano wire to help add rigidity, but it would seriously dig into the plastic on my previous setup. Right now I'm using a length of spare nylon filament from a PrusaMK3 setup, but it's not long enough. I know some folks run things through a cable gland and I am pondering this while also just putting the spool underneath the printer so it can go up and over (that's how I have my V0 setup). Any other thoughts perhaps? This thing only prints PLA and maybe on rare occasion PETG so I don't plan on ever having covers, which gives me plenty of room along the top.

Anyways just curious to see how folks setup their umbilical for XOLs, TLDR

Also as an aside any tips to help make sensorless homing of the Y less bangy/clungy that'd be appreciated - I tried several combinations of speed and stalls but while the X seems to have the perfect, quiet, touch, the Y doesn't exactly have finesse.

I've been happy enough with the setup but it is a little janky. I did buy some piano wire to help add rigidity, but it would seriously dig into the plastic on my previous setup. Right now I'm using a length of spare nylon filament from a PrusaMK3 setup, but it's not long enough. I know some folks run things through a cable gland and I am pondering this while also just putting the spool underneath the printer so it can go up and over (that's how I have my V0 setup). Any other thoughts perhaps? This thing only prints PLA and maybe on rare occasion PETG so I don't plan on ever having covers, which gives me plenty of room along the top.

Anyways just curious to see how folks setup their umbilical for XOLs, TLDR

Also as an aside any tips to help make sensorless homing of the Y less bangy/clungy that'd be appreciated - I tried several combinations of speed and stalls but while the X seems to have the perfect, quiet, touch, the Y doesn't exactly have finesse.