Akio

Member

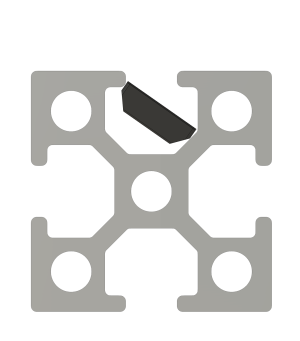

So you built a Voron 0 and noticed too late that you forgot to preload a hex nut? Or you chose to do a mod to your V0 that needs some additional hex nuts in your extrusions? If you have a makerbeam style aluminium extrusion you probably will need to disassemble your frame, at least partly. But when you have an LDO style frame you have the option to buy some drop in nuts. For example https://west3d.com/de-de/products/1515-extrusion-m3-slide-in-nuts-20pcs or https://kb-3d.com/store/extrusion-f...515-extrusions-m3-20-piece-1677362605618.html

They are absolutely awesome and if you have the chance to get them you should do so. It is definitively worth every cent, when you don't have to rip apart your perfectly square frame. Here is also a video how they are used:

But in Germany you can't buy them. But what you can buy is M3 square nuts. They are available for a few bucks on Amazon. And from a M3 square nut, you can easily make your own drop in nut. Lets have a look at what needs to be done:

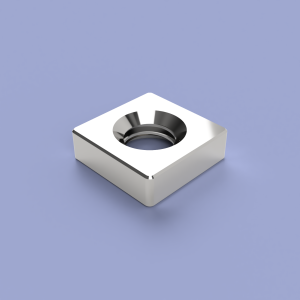

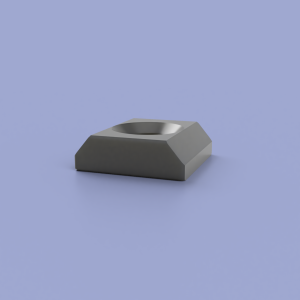

This is our square nut:

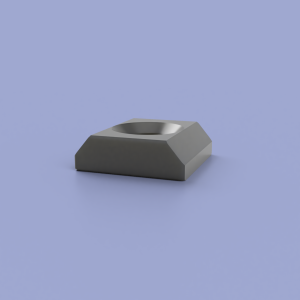

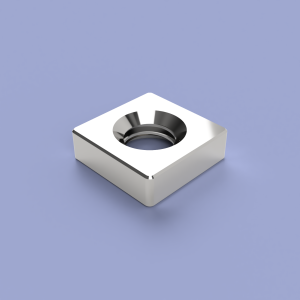

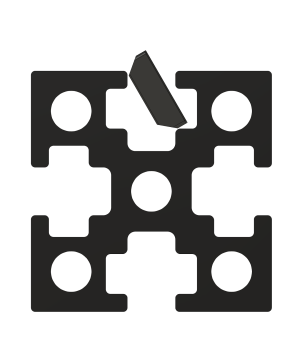

This is what you want to have:

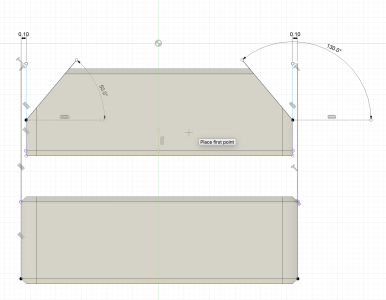

Lets compare them:

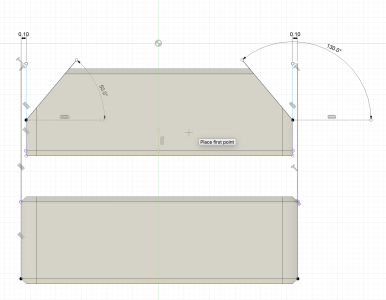

To get from a square nut to a drop in nut, you need to file of 0.1mm from the left and from the right side, and then roughly a 40° angle from the top side.

But isn't it tedious to make these by hand? No. You can make one in less than a minute. Definitely much faster than the disassembly of the frame.

Here are the steps:

1. You need to clamp the square nut in a vise like this:

2. Then you file of the 0.1mm from the side. With an old file I had lying around it was roughly 10-15 strokes for me. You will need to find out how many strokes you need based on your equimpment.

3. Next you file of the 40° angle from the top. Don't worry, you don't need to be precise. For me it took another 10 strokes. Again you will need to find out how many strokes you need based on your equimpment.

4. Then you need to turn the nut in the vise and repeat this for the other side (Step 2 and 3).

When you have completed the steps above try if the nut will slide easily into an 1515 extrusion or if you need to remove some more material.

Again - it does not work for makerbeam style 1515 extrusions. There is not enough room that they will slide/roll in.

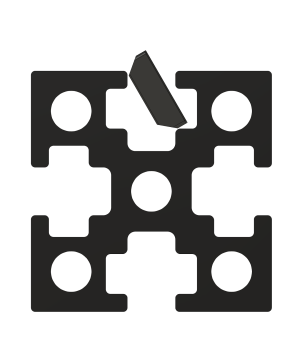

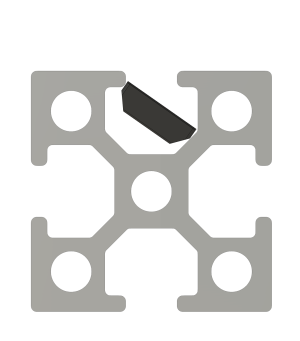

For LDO style 1515 extrusions it looks like this:

I hope that with this post I could save some frames from disassembly...

They are absolutely awesome and if you have the chance to get them you should do so. It is definitively worth every cent, when you don't have to rip apart your perfectly square frame. Here is also a video how they are used:

But in Germany you can't buy them. But what you can buy is M3 square nuts. They are available for a few bucks on Amazon. And from a M3 square nut, you can easily make your own drop in nut. Lets have a look at what needs to be done:

This is our square nut:

This is what you want to have:

Lets compare them:

To get from a square nut to a drop in nut, you need to file of 0.1mm from the left and from the right side, and then roughly a 40° angle from the top side.

But isn't it tedious to make these by hand? No. You can make one in less than a minute. Definitely much faster than the disassembly of the frame.

Here are the steps:

1. You need to clamp the square nut in a vise like this:

2. Then you file of the 0.1mm from the side. With an old file I had lying around it was roughly 10-15 strokes for me. You will need to find out how many strokes you need based on your equimpment.

3. Next you file of the 40° angle from the top. Don't worry, you don't need to be precise. For me it took another 10 strokes. Again you will need to find out how many strokes you need based on your equimpment.

4. Then you need to turn the nut in the vise and repeat this for the other side (Step 2 and 3).

When you have completed the steps above try if the nut will slide easily into an 1515 extrusion or if you need to remove some more material.

Again - it does not work for makerbeam style 1515 extrusions. There is not enough room that they will slide/roll in.

For LDO style 1515 extrusions it looks like this:

I hope that with this post I could save some frames from disassembly...

Last edited: