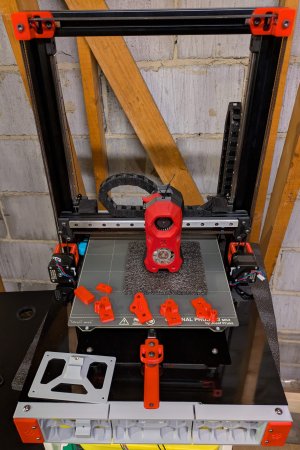

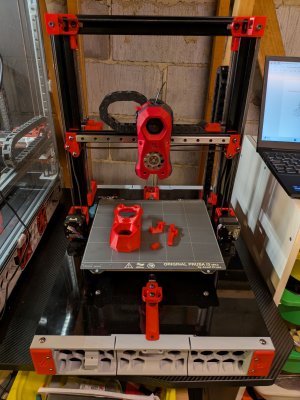

I thought I would log this one here as this printer has a bit of history and it is time to rebuild it properly. I'd say there are a few Switchwires out there that have some dodgy first ABS prints on them

I purchased early 2024 to dip my toe in the Voron waters, so to speak. I purchased second hand in bits and it had the initial prints with it what were out-of-this-world terrible.

All in all, it had a very good base but I did the absolute minimum necessary to get it running. Now I have a second functional printer (V2.4) it is time to bring it up to spec and replace some of those rather crunchy prints.

What is it now?:

LDO SW frame

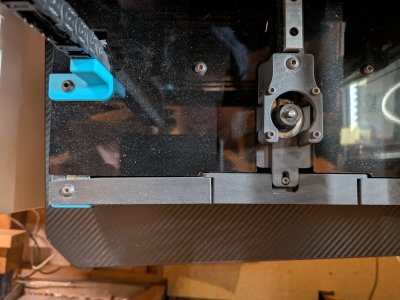

LDO rails (one has a lovely crunchy breakfast cereal feel to it)

LDO steppers 4240's from memory

Stealthburner, running Revo Voron 40w & CW2 (I updated the toolhead on its initial re-assembly as it was a mess)

BTT E3 V3 main board

Genuine PRUSA MK52 heatbed

Pi Zero

Meanwell 350w 24v & 5v

Keyback - the incorrect one unfortunately.

What am I changing - updating?

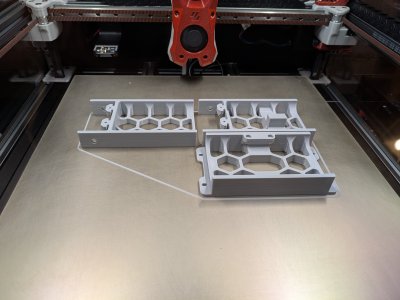

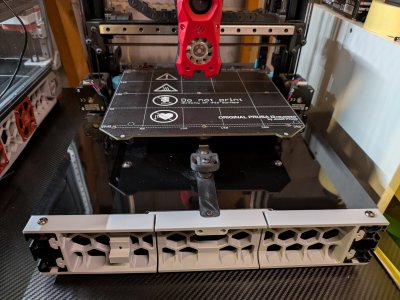

All of the prints not yet changed (i.e most of them)

The one shagged LDO rail unless you can reball it? I already cleaned and re-greased but this one feels like the balls are shagged.

Steppers - I have some LDO 4248's I got second hand a while back I will drop in - I mean, why not

Toolhead board - I have a Nighthawk in my 2.4 so thinking to go that direction for this.

Enclosure - It came with one but it is god-dam-awful - will see how I can change it to be a bit more user friendly for easy removal.

BTT touch screen - hopefully it fits the LDO RevC print for the front.

Pi 4 to run the screen

Underdeck wiring / general tidy up

I am playing with colours but I am heading toward gray / red / black with some tasteful lighting in behind the front grills.

I purchased early 2024 to dip my toe in the Voron waters, so to speak. I purchased second hand in bits and it had the initial prints with it what were out-of-this-world terrible.

All in all, it had a very good base but I did the absolute minimum necessary to get it running. Now I have a second functional printer (V2.4) it is time to bring it up to spec and replace some of those rather crunchy prints.

What is it now?:

LDO SW frame

LDO rails (one has a lovely crunchy breakfast cereal feel to it)

LDO steppers 4240's from memory

Stealthburner, running Revo Voron 40w & CW2 (I updated the toolhead on its initial re-assembly as it was a mess)

BTT E3 V3 main board

Genuine PRUSA MK52 heatbed

Pi Zero

Meanwell 350w 24v & 5v

Keyback - the incorrect one unfortunately.

What am I changing - updating?

All of the prints not yet changed (i.e most of them)

The one shagged LDO rail unless you can reball it? I already cleaned and re-greased but this one feels like the balls are shagged.

Steppers - I have some LDO 4248's I got second hand a while back I will drop in - I mean, why not

Toolhead board - I have a Nighthawk in my 2.4 so thinking to go that direction for this.

Enclosure - It came with one but it is god-dam-awful - will see how I can change it to be a bit more user friendly for easy removal.

BTT touch screen - hopefully it fits the LDO RevC print for the front.

Pi 4 to run the screen

Underdeck wiring / general tidy up

I am playing with colours but I am heading toward gray / red / black with some tasteful lighting in behind the front grills.