- Printer Model

- Voron 24 350mm

- Extruder Type

- Other

- Cooling Type

- Afterburner

Ive just a little question regarding Problems with my Z high and inconsistent 1 Layer on some Areas of my Bed. It is warped a bit.

I tried several things to overcome this, including bed_mesh with strange unpredictable outcomes.

I used 0.03 mm Sticky aluminum foil to even out the bed manually. That helped the most as of yet.

QGL is normaly leveling out after second pass below 0.005

I have the feeling, that my steppers on Z do only 0.1mm moves. That would explain a lot.

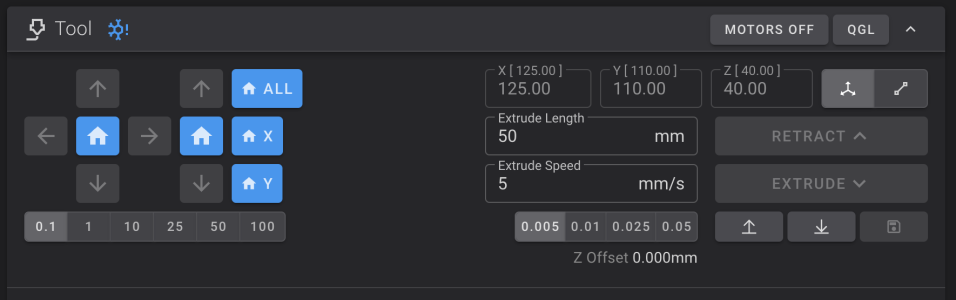

Can somebody confirm that when in Fluidd

on the Movement Console it's pssible to do

0.05 mm steps? In my case i can only do 0.1 mm steps otherwise nothing happens.

As well in print.cfg when changing z offset manually on bottom of code by 0.05 it changes nothing for the first layer

My steppers are 1.8 degree and in 16steps configuerd.

Im thankfull for any idea that leads to solving this issue i have for too long now.

Thanks

chris

Klipper newest

Moonraker newest

Fluidd newest

Fystec 1.0 firmware is about 1year old

slicer: Cura or Prusa

I tried several things to overcome this, including bed_mesh with strange unpredictable outcomes.

I used 0.03 mm Sticky aluminum foil to even out the bed manually. That helped the most as of yet.

QGL is normaly leveling out after second pass below 0.005

I have the feeling, that my steppers on Z do only 0.1mm moves. That would explain a lot.

Can somebody confirm that when in Fluidd

on the Movement Console it's pssible to do

0.05 mm steps? In my case i can only do 0.1 mm steps otherwise nothing happens.

As well in print.cfg when changing z offset manually on bottom of code by 0.05 it changes nothing for the first layer

My steppers are 1.8 degree and in 16steps configuerd.

Im thankfull for any idea that leads to solving this issue i have for too long now.

Thanks

chris

Klipper newest

Moonraker newest

Fluidd newest

Fystec 1.0 firmware is about 1year old

slicer: Cura or Prusa