Yezariael

Well-known member

no problem at allYeah... Convincing... I need one.. Was it easy to fix?

no problem at allYeah... Convincing... I need one.. Was it easy to fix?

at the moment I use this: https://www.printables.com/model/424248-beacon-probe-mount-for-voron-tap-stealthburnerYes but how did you do? Did you designed new parts?

as aluminium is not magnetic it should not matter I guess.THX

Creaping is a thing I hate...

Have to think if i should cnc the complete head of aluminum. ( not font of that much of work, so will see if i can live without it, also alu might disturb the function of the probe. tbd.

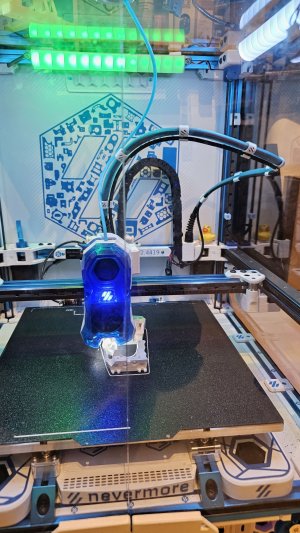

The rainbow LED while it does that is a nice touchGot mine installed and working. It's pretty nice.

USB cable is about 1.8m long, so absolutely enoughThe rainbow LED while it does that is a nice touchI was gonna ask if the USB cable was long enough but I see you're running an umbilical (and thus a CAN toolhead?). I was worried about the USB cable being long enough for the regular (non-umbilical) setup on a 350. That plus having to mess with the cable chains again have been the main reasons I haven't picked one up - yet!

USB Type A 2.0 which is what Beacon uses, only uses 4 wires. So with CAN and Beacon I am backup to 8 wires plus PTFE going to the tool head. About half what it was with Chains.Hmmm follow up Q makes me wonder then if they can cram a USB interface on the Beacon, then making a USB toolhead sounds in reach, although to then hook the Beacon up to it, it would also need a hub on board? Kinda crazy we finally have some cool uses for CAN and Beacon comes out and is like "Lol that's not fast enough"Oh well, progress is progress! Even going down to 2 cables is still a worthy jump for me. I've had to replace my main cable bundles once already in my 2.4 and my SB LED cable has a break in it that I've been putting off.

The BTT SB2240 has a USB C port on the PCBHmmm follow up Q makes me wonder then if they can cram a USB interface on the Beacon, then making a USB toolhead sounds in reach, although to then hook the Beacon up to it, it would also need a hub on board? Kinda crazy we finally have some cool uses for CAN and Beacon comes out and is like "Lol that's not fast enough"Oh well, progress is progress! Even going down to 2 cables is still a worthy jump for me. I've had to replace my main cable bundles once already in my 2.4 and my SB LED cable has a break in it that I've been putting off.

Interesting. This is what I've planned to move to. I have the BTT SB0000 EBB2209. Is the cable USB-C?The BTT SB2240 has a USB C port on the PCB