Laserbea4k43

Well-known member

- Printer Model

- Voron 2.4 350

- Extruder Type

- Clockwork 2

- Cooling Type

- Stealthburner

Hello,

After months of not using my printer, I've come back to it and discovered voron tap. I haven't been able to get any of my prints to stick to the bed, however.

Somewhere after the first few layers, a part gets caught on the nozzle and pulls the print from the bed.

My chamber is at about 40C+ and I print at 110 for the bed and 235 on the nozzle.

My fan speed is 55% after the first 2 layers (is that too early? should I slow my fan down?)

I've scrubbed my PEI sheet, cleaned it with alcohol and a clean microfiber towel.

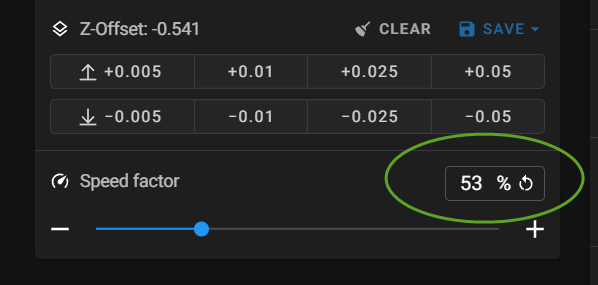

These are my results when I change my switch offset:

Any advice?

Thanks.

After months of not using my printer, I've come back to it and discovered voron tap. I haven't been able to get any of my prints to stick to the bed, however.

Somewhere after the first few layers, a part gets caught on the nozzle and pulls the print from the bed.

My chamber is at about 40C+ and I print at 110 for the bed and 235 on the nozzle.

My fan speed is 55% after the first 2 layers (is that too early? should I slow my fan down?)

I've scrubbed my PEI sheet, cleaned it with alcohol and a clean microfiber towel.

These are my results when I change my switch offset:

I can't seem to consistently keep the result of the last change, .008000 and i've taken the offset down as far as .25 to see what would happen. It hasn't gotten any better.Switch offset @ .48 | 01:19:42 // Z-CALIBRATION: ENDSTOP=0.007 NOZZLE=-0.025 SWITCH=6.035 PROBE=6.470 --> OFFSET=-0.070500

Switch offset @ .49 | 01:20:13 // Z-CALIBRATION: ENDSTOP=0.007 NOZZLE=-0.060 SWITCH=6.037 PROBE=6.487 --> OFFSET=-0.100500

Switch offset @ .47 | 01:25:08 // Z-CALIBRATION: ENDSTOP=0.007 NOZZLE=-0.030 SWITCH=6.080 PROBE=6.527 --> OFFSET=-0.053000

Switch offset @ .45 | 01:30:39 // Z-CALIBRATION: ENDSTOP=0.007 NOZZLE=-0.023 SWITCH=6.090 PROBE=6.542 --> OFFSET=-0.020500

Switch offset @ .43 | 01:37:35 // Z-CALIBRATION: ENDSTOP=0.007 NOZZLE=-0.025 SWITCH=6.085 PROBE=6.532 --> OFFSET=-0.008000

Any advice?

Thanks.