vorondesignlover

Active member

Hello to all,

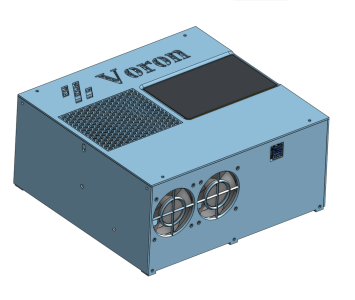

I'm going to build my first Voron 2.4 R2 350mm (all the highest specs selected in the configurator) with the following enhancements:

Thanks to all

I'm going to build my first Voron 2.4 R2 350mm (all the highest specs selected in the configurator) with the following enhancements:

- 48v system

- Rapido V2 UHF hotend (PT1000 ???)

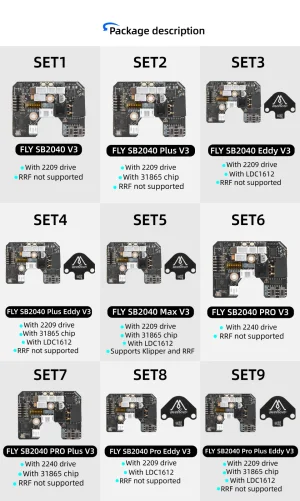

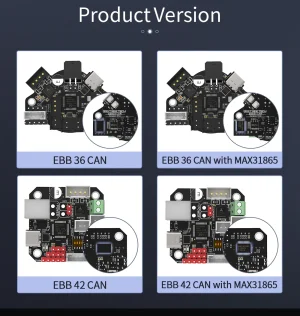

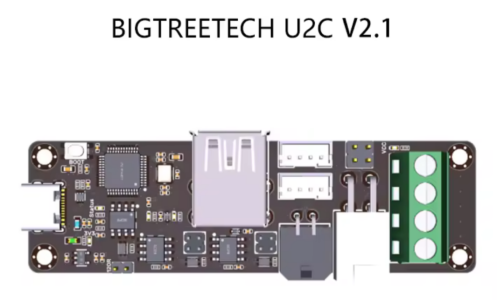

- CANBus

- Galileo (for a setup like this I suppose is a better choice rather than the stealthburner)

- Any other enhancement I'm currectly not aware of, in the future or now (if I'm still within my budget). Suggestions are more than welcome.

- no need for an external host like a Raspberry

- better CANBus integration (CAN-FD support and no extra components other than the CAN Toolhead)

- many other advantages (interfaces, eMMC, wifi, thermal handling, onboard sensors etc), but the first twos are the ones that attract me more

- A site that review Voron control boards, for high performant machines recommends an Orange Pi 5B with as much RAM as one could get and this is going to be very expensive. I'm wondering if the FLY Gemini is at least on pair in terms of performance. I don't want to find myself, now or when I do an upgrade, forced to buy a new whole board due to "not enough system resources". With the Octopus I feel much safer because I can just use a cheap x86 Mini-ITX board as host.

- It appears to use a customized (and closed source) version of Klipper. This is usually a valid reason for me to give up and look into something else, but I'm new to the world of 3D printers and someone may give me a valid reason to close an eye.

- I've read that it comes with 8 stepper driver sockets, but in their picture I only see 4 sockets (which is not even close to the 7+ Stepper outputs board listed in the BOM)

- I can't find any review on their AE product page, just some unanswered questions: "Is possible use dual Z Step motors with this board?", "What should I register in Clipper for this board to connect adxl345?".

- I may have to go into advanced cooling and while I saw any kind of cooling running in Octopus boards, I have no idea if this board can handle this

Thanks to all