Is there a foundation drawing anywhere that is Fusion 360 based.

I need to build a new hotend / extruder combination, I always model my systems in Fusion both for assembly and motion.

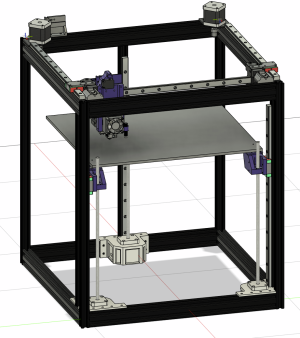

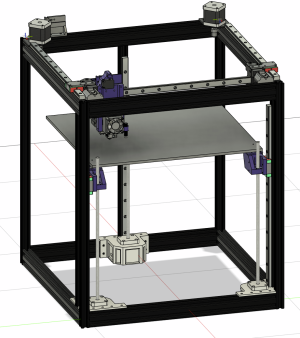

I have a 'CoreXY' that started life as a Rat Rig but it was never built as such. I think the picture below offers some idea.

There are three MGN15 rails for Z, three for XY including one that carries the hotend / extruder which is currently an E3D Hemera. the bed is 'free floating' on a 3 point Kinematic / Maxwell mount, it is held in place only by its own weight. Control is done using a Duet3d 6HC, has been in service a couple of years.

I want to change from the Hemera to a Stealthburner architecture, I have in mind some parts - potentially a Galileo 2 but for sure I want to introduce a Voron Revo PZ - what I need is a foundation CAD drawing that I can use to create this 'idea' in a 3D model space within Fusion 360 - and be able to experiment with different extruder models before committing to a parts list. I am not really concerned with massive flow rates but I do care about accuracy, using high tempertature materials and minimising artefacts as I use this for creating scale model parts some of which are structural. The Hemera has been a problem from day one because of its mass that constrains acceleration, introduces artefacts and also its propensity to ooze and over extrude.

I have the Stealthburner files from the Github but they seem to have a fair number of features aimed at specific hardware, none of which are the architecture I am looking for, for sure they don't work with an MGN15 rail, the Galileo 2 nor the Voron Revo, but it is hard to understand which holes are intended for what.

I've read quite a bit about the Stealthburner and is why I am exploring it - I like the idea of being able to switch out the tool head without disturbing the rest for one. If I had a base drawing I could tailor it for the new parts by positioning them and then modelling around them - sure I could 100% design but then I couldn't seek off the shelf 'bits' ....

I'm OK with printing the parts but I would like to be able perhaps to get them pre made in a high temperature tolerant material - which may constrain me to things like the Bondtech Lite or Pro since they are already accounted for - but I cannot find a hot end support available for the Voron Revo or even identify how the Revo and Bondtech could be combined - which is why I want to model all this. The available CAD files from E3D and Bondtech aren't the best either.

Can anyone support with where to start ?

I need to build a new hotend / extruder combination, I always model my systems in Fusion both for assembly and motion.

I have a 'CoreXY' that started life as a Rat Rig but it was never built as such. I think the picture below offers some idea.

There are three MGN15 rails for Z, three for XY including one that carries the hotend / extruder which is currently an E3D Hemera. the bed is 'free floating' on a 3 point Kinematic / Maxwell mount, it is held in place only by its own weight. Control is done using a Duet3d 6HC, has been in service a couple of years.

I want to change from the Hemera to a Stealthburner architecture, I have in mind some parts - potentially a Galileo 2 but for sure I want to introduce a Voron Revo PZ - what I need is a foundation CAD drawing that I can use to create this 'idea' in a 3D model space within Fusion 360 - and be able to experiment with different extruder models before committing to a parts list. I am not really concerned with massive flow rates but I do care about accuracy, using high tempertature materials and minimising artefacts as I use this for creating scale model parts some of which are structural. The Hemera has been a problem from day one because of its mass that constrains acceleration, introduces artefacts and also its propensity to ooze and over extrude.

I have the Stealthburner files from the Github but they seem to have a fair number of features aimed at specific hardware, none of which are the architecture I am looking for, for sure they don't work with an MGN15 rail, the Galileo 2 nor the Voron Revo, but it is hard to understand which holes are intended for what.

I've read quite a bit about the Stealthburner and is why I am exploring it - I like the idea of being able to switch out the tool head without disturbing the rest for one. If I had a base drawing I could tailor it for the new parts by positioning them and then modelling around them - sure I could 100% design but then I couldn't seek off the shelf 'bits' ....

I'm OK with printing the parts but I would like to be able perhaps to get them pre made in a high temperature tolerant material - which may constrain me to things like the Bondtech Lite or Pro since they are already accounted for - but I cannot find a hot end support available for the Voron Revo or even identify how the Revo and Bondtech could be combined - which is why I want to model all this. The available CAD files from E3D and Bondtech aren't the best either.

Can anyone support with where to start ?