- Printer Model

- Voron 2.4r2

- Extruder Type

- Clockwork 2

- Cooling Type

- Afterburner

Hello all,

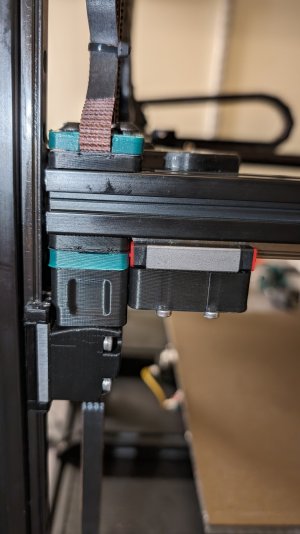

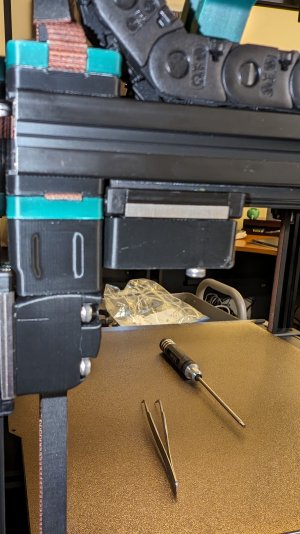

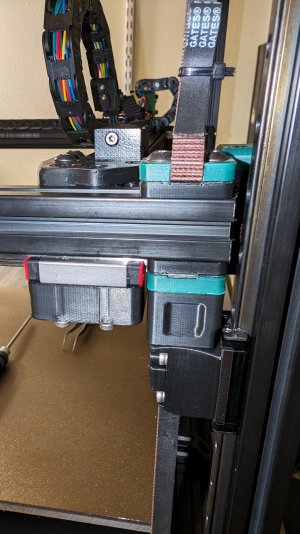

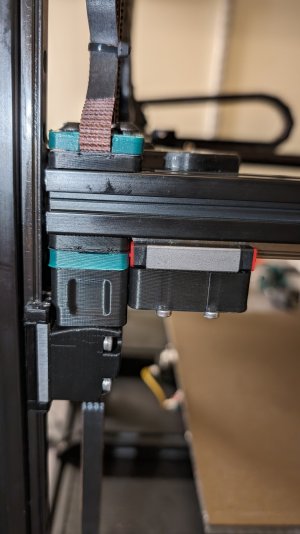

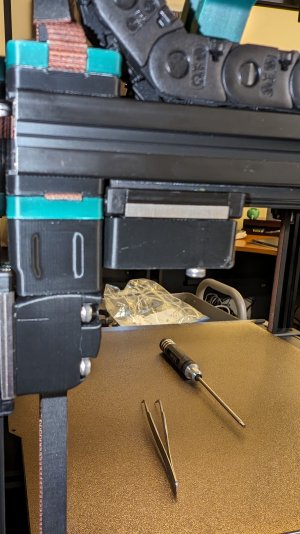

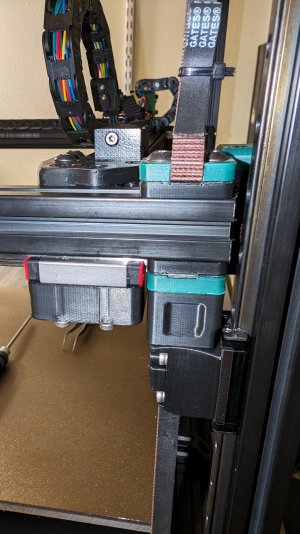

I seem to have a racking issue I cant shake. Attached are photos of each corner of the gantry where the linear rail sleds are. You can see there is a pretty noticeable gap on one side compared to the other. I have followed Neros deracking video and AndrewEllises deracking guide without much luck. Anyone have any ideas about what could be going on?

350mm Voron 2.4r2

Omron probe

Afterburner toolhead

Front right

Right rear

Front left

Left rear

I seem to have a racking issue I cant shake. Attached are photos of each corner of the gantry where the linear rail sleds are. You can see there is a pretty noticeable gap on one side compared to the other. I have followed Neros deracking video and AndrewEllises deracking guide without much luck. Anyone have any ideas about what could be going on?

350mm Voron 2.4r2

Omron probe

Afterburner toolhead

Front right

Right rear

Front left

Left rear