Durahl

Well-known member

Do different Nozzle Sizes require different calibration values for the Extrusion Multiplier and Pressure Advance?

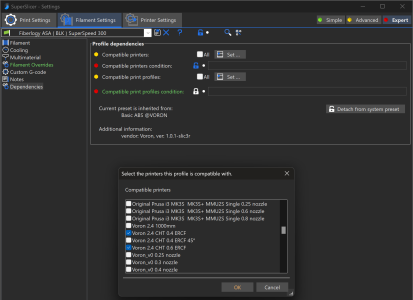

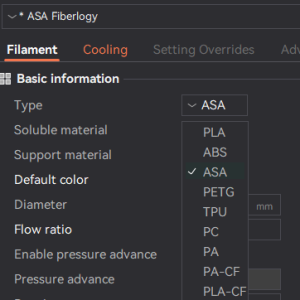

In the case of SuperSlicer ( which seems to get more and more outdated as time progresses ) the most obvious laymen's solution seems to be to create copies of the same filament with the various values, then assigning them in the dependencies to a compatible Printer Profile in which the Nozzle is defined. The other being an If / Else Logic buried somewhere?

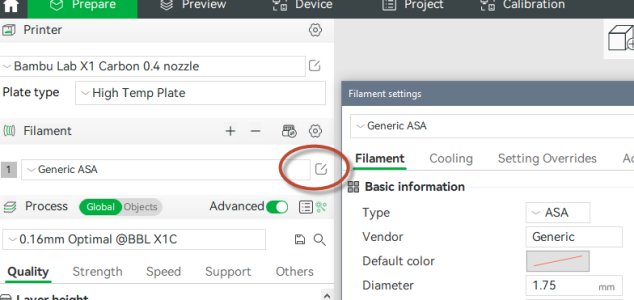

How would / could this be done in something like OrcaSlicer which doesn't seem to have the dependencies feature a Filament could be assigned to?

In the case of SuperSlicer ( which seems to get more and more outdated as time progresses ) the most obvious laymen's solution seems to be to create copies of the same filament with the various values, then assigning them in the dependencies to a compatible Printer Profile in which the Nozzle is defined. The other being an If / Else Logic buried somewhere?

How would / could this be done in something like OrcaSlicer which doesn't seem to have the dependencies feature a Filament could be assigned to?