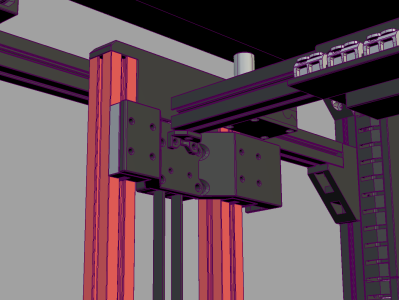

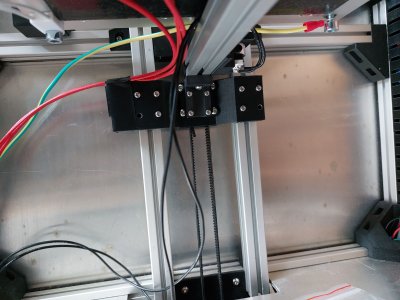

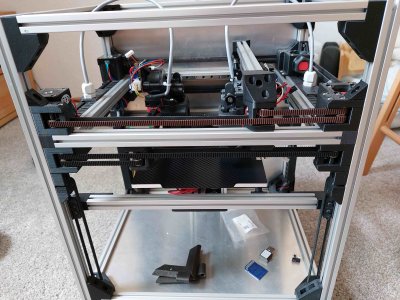

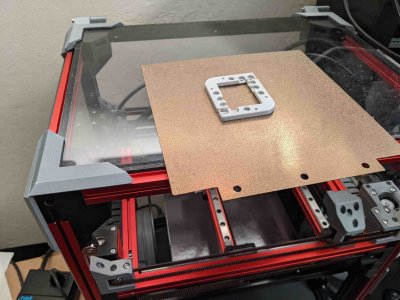

Dueling Zero is a Dual Gantry V0 mod.

Two extruders, no compromises. Kinda like an IDEX... but rarer, and more interesting, if you're into the "outside lands" of Voron mods.

Since the original release livestream this year on the DoomCube Discord, I've added a few things, and I figured this thread would be a way to share some of those updates that haven't made their way to GitHub yet, because I don't share things broadly until I trust that they'll work for you out-of-the-box. Read to the end for a small announcement, too...

Anyway, time to put this printer to work!

(1) New enclosure added, based on ZeroPanels v3!

Take a look, as this video walks through the new (unreleased) panels and design history:

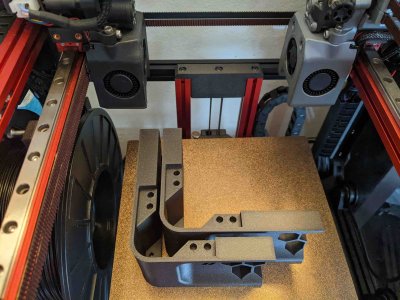

(2) Internal spool holders!

Yes, this V0 fits two internal spools, with no loss of travel.The custom design uses flexure-loaded 608 top bearings with custom-fit plastic rollers on top, with 2x 608 bearings on the bottom. Should double as a convenient filament dryer, though with ABS as the main material here, that's not a big deal. But in the future, nylons and others could be interesting.

(3) ZeroFilter added!

It's VHBed to the bottom for now, until I can select and print a larger rear-of-enclosure design. Sacrifices a tiny bit of Z, but the Z is completely unoptimized anyway, so no biggie.

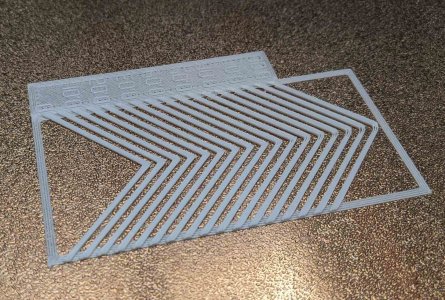

(4) PA tuned using Ellis' new Pattern method!

After these changes, I did a PA tune in 6m, using Ellis' latest pattern generator. If you haven't seen it yet - check it out! It's awesome. So much better than the prior method of printing a box and measuring.

The results: :chefkiss

The first ABS print worked out nicely, using known-good V0 profiles. Inland matte gray hides all sins (VFAs, ringing... it's like the vantablack of gray), so I'm kinda cheating here, but next up will be KVP MSIL, which is the opposite: it reveals all flaws.

There's plenty of additional stuff before this can be considered done. For example, the bottom board is foam, so that's probably the next-most-important item, to switch out to ABS.

And I want to do a complete change-out of the electronics if I'm going to do that, as well as return to the software and auto-tuning side.

But I'm excited for at least two reasons:

- "a larger V0" - basically, this is "just" a Tri-Zero Plus50 when you use one extruder, with a roughly ~170x170 square build volume - means I can in theory do full plates overnight, as well as slightly longer parts that just couldn't be done on a 120 bed like the others I have.

- there's likely to be another D0 on the horizon soon, and it's not my build. Stay tuned!

Stay tuned... I'll try to keep this updated with major improvements. Feel free to use this thread for questions and comments, too, especially once you've looked through the enormous amount of loving-crafted documentation on the GitHub, including a full design walkthough. I appreciate any motivators here, as this thing alternates between 'work' and 'intensely rewarding' in my mind.