Vorkosigan

Member

- Printer Model

- V0.1

- Extruder Type

- Other

- Cooling Type

- Other

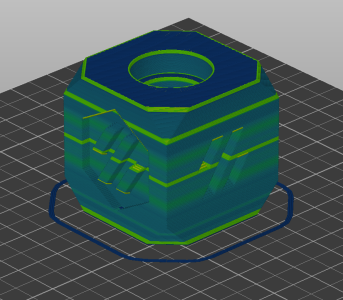

My V0 prints great for the most part, however, I've noticed some inconsistencies in my prints that I haven't been able to fix and I could use some input. I have seen other people ask about seemingly identical issues, but never did see any follow up to say they fixed it.

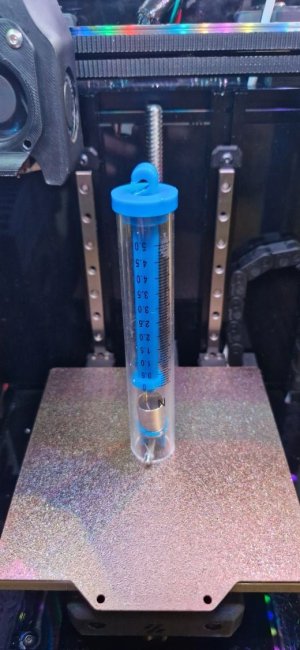

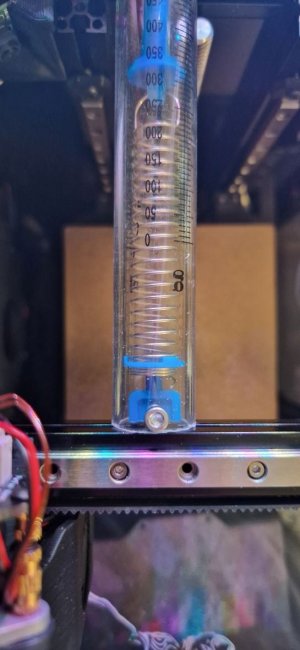

I'm including a picture and I've circled in red the problem areas. On the cylindrical part, there are printed threads on the inside that seem to line up with the inconsistent layer lines. The printed the cylinder on the left and the block on the right are just basic shapes I printed to see if the problem would still be there, but it wasn't.

Hoping that someone has some suggestions on what to try.

I'm including a picture and I've circled in red the problem areas. On the cylindrical part, there are printed threads on the inside that seem to line up with the inconsistent layer lines. The printed the cylinder on the left and the block on the right are just basic shapes I printed to see if the problem would still be there, but it wasn't.

Hoping that someone has some suggestions on what to try.