igiannakas

Member

- Printer Model

- 2.4 350

- Extruder Type

- Galileo

- Cooling Type

- Stealthburner

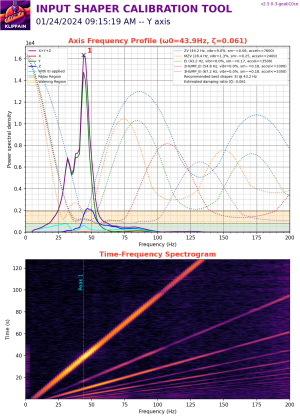

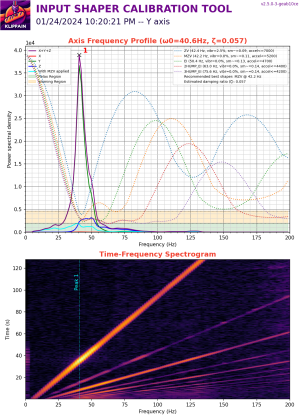

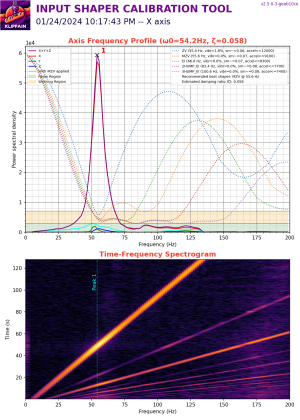

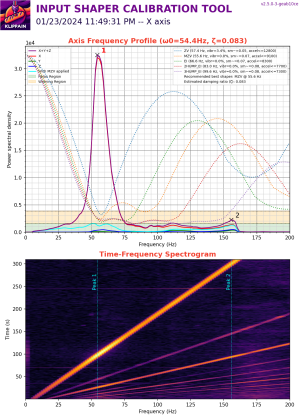

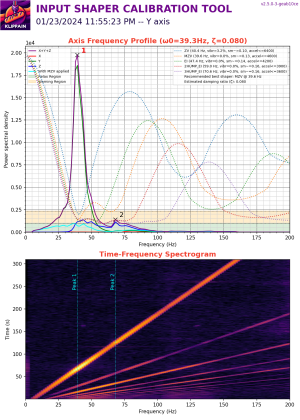

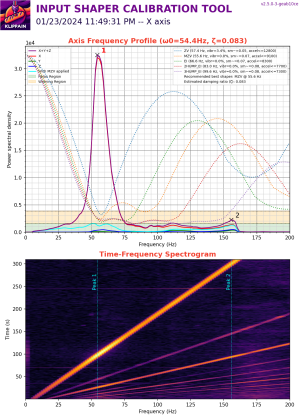

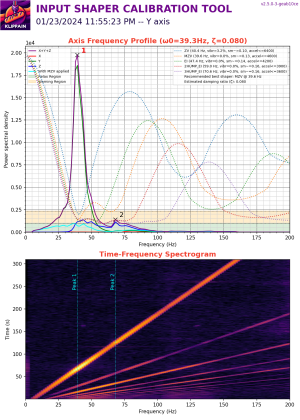

I’ve recently completed my build of the R2.4 350mm with plastic tap. Running input shaper and tuning it and seeking some feedback on whether the below graphs are ok and what more can be done to improve them further to potentially increase accelerations a bit or clean them up a bit further?

Printer is on the floor so not much wobbling.

Printer is on the floor so not much wobbling.