I just finished building my LDO 350 2.4. I need a few beers after that... It was A LOT more work than building my MK3. My first print (ABS) had poor adhesion to the LDO bed. (I didn't apply anything but just cleaned it well with alcohol). For 2nd print I used Kapton tape with ABS juice on top of that. So far the adhesion seems strong. Can ABS be printed reliably on the LDO textured bed without some type of adhesive applied to it?

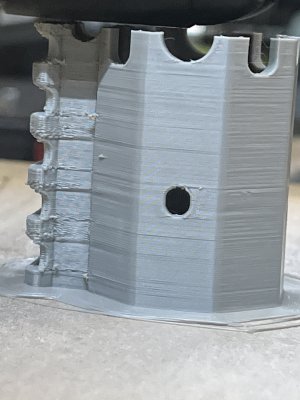

The print quality from both prints on the left side is poor compared to the right side. It's worse in 0.2 than 0.1. First print was at 0.1 and 2nd 0.2 layer height, AMZ3D ABS, 240 nozzle, 110 bed & chamber at 57. There are unsupported overhangs on the back from where ridges are being created along the path of the nozzle way past the end of the overhang. Guessing maybe a few variables at work here beyond my pay grade. Prior to the Voron I basically just printed in PETG or PLA. Any suggestions beyond the Initial LDO setup tips to do? I just looked at the secondary tuning section and have not yet done the audio test for belt tensioning. Overall the ABS quality to me appears fair at best.

The print quality from both prints on the left side is poor compared to the right side. It's worse in 0.2 than 0.1. First print was at 0.1 and 2nd 0.2 layer height, AMZ3D ABS, 240 nozzle, 110 bed & chamber at 57. There are unsupported overhangs on the back from where ridges are being created along the path of the nozzle way past the end of the overhang. Guessing maybe a few variables at work here beyond my pay grade. Prior to the Voron I basically just printed in PETG or PLA. Any suggestions beyond the Initial LDO setup tips to do? I just looked at the secondary tuning section and have not yet done the audio test for belt tensioning. Overall the ABS quality to me appears fair at best.