Jqw767

Member

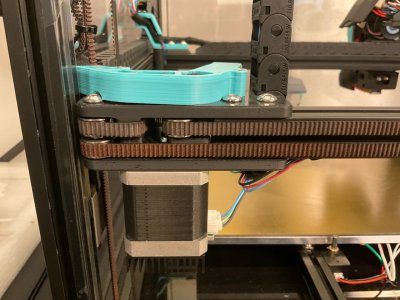

- Printer Model

- Voron 2.4 Formbot 350 kit

- Extruder Type

- Clockwork 2

- Cooling Type

- Stealthburner

Hi Voroneers,

after Reddit went private in the middle of my Troubleshooting a couple of days ago I still experience severe layer shift on the x/y axis on my pretty new Formbot 350mm 2.4.

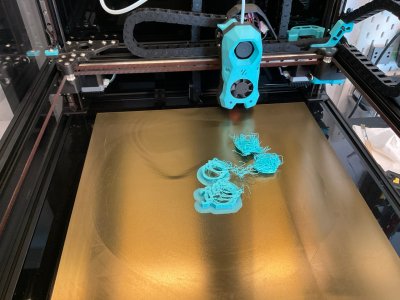

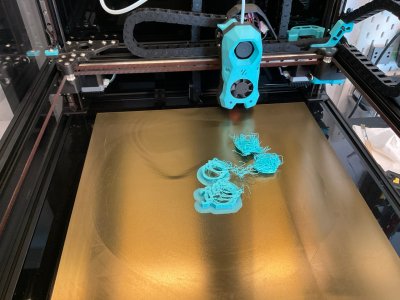

Below you can see the problem description, things I‘ve tried and a couple of pics.

Problem description:

- significant and continuous layer shift in +x and +y direction after a couple of layers

- no specific layer when it starts, can be on 2nd layer or 15th layer, but once it starts it continues to drift/skip

- skipping can be heard where the belt skips on at least one of the motors

Background Info:

- Formbot Kit, Moons steppers, TMC2209 (Run_current 1.0A, but also tried 1.1, 1.2A)

- setup worked fine for about 60h print time, problem started suddenly, always happens since

Hypothesis and trials:

1) TMC2209 voltage too low?

- current and previously used setting: 1.0A (Run_current define only), tried 1.1 and 1.2A, with 100*C buildülate Temp motors are running quite hot, heatsinks installed

- Moons rated for 2.0A max. With 2.0A x 0,707 = 1.414A would be over the max limit for TMC2209 (max 1.2A if I read correctly)

- To do: switch the TMC2209 from a z Motor to the x and y motors

2) Belt tensioning incorrect and/or Belt path incorrect

- used the spectrum analyzer, as well as carbon drive app, compared to the Nero3D YouTube guide (and sound), seems ok

- re-seated the whole belt incl. belt path, ensured smooth run -> did it the right way finally! Solved the issue!

3) Linear rail friction/lubrication:

- took apart the x rail (MGN12 as this is the only one that does not slide just by gravity, cleaned and re-lubed. Runs free, but carriage does not fall freely just by gravity

- cleaned and re-lubed y rails (MGN9)

4) Motor Wires broken?

- wires not replaced yet, but only 60h of runtime…

- bent chains/wires while doing x/y movement to provoke intermittent breaks in the wire - nothing

- marked belt/motor position, let layers skip, compared: right motor „A Motor“ as described in the Voron Manual seems to be the culprit, although the marking on the belt was basically gone for both, but the motor position was different

Any further ideas or possible root-causes? I will keep this updated in the original post up here, also when root cause is found.

Pictures:

after Reddit went private in the middle of my Troubleshooting a couple of days ago I still experience severe layer shift on the x/y axis on my pretty new Formbot 350mm 2.4.

Below you can see the problem description, things I‘ve tried and a couple of pics.

Problem description:

- significant and continuous layer shift in +x and +y direction after a couple of layers

- no specific layer when it starts, can be on 2nd layer or 15th layer, but once it starts it continues to drift/skip

- skipping can be heard where the belt skips on at least one of the motors

Background Info:

- Formbot Kit, Moons steppers, TMC2209 (Run_current 1.0A, but also tried 1.1, 1.2A)

- setup worked fine for about 60h print time, problem started suddenly, always happens since

Hypothesis and trials:

1) TMC2209 voltage too low?

- current and previously used setting: 1.0A (Run_current define only), tried 1.1 and 1.2A, with 100*C buildülate Temp motors are running quite hot, heatsinks installed

- Moons rated for 2.0A max. With 2.0A x 0,707 = 1.414A would be over the max limit for TMC2209 (max 1.2A if I read correctly)

- To do: switch the TMC2209 from a z Motor to the x and y motors

2) Belt tensioning incorrect and/or Belt path incorrect

- used the spectrum analyzer, as well as carbon drive app, compared to the Nero3D YouTube guide (and sound), seems ok

- re-seated the whole belt incl. belt path, ensured smooth run -> did it the right way finally! Solved the issue!

3) Linear rail friction/lubrication:

- took apart the x rail (MGN12 as this is the only one that does not slide just by gravity, cleaned and re-lubed. Runs free, but carriage does not fall freely just by gravity

- cleaned and re-lubed y rails (MGN9)

4) Motor Wires broken?

- wires not replaced yet, but only 60h of runtime…

- bent chains/wires while doing x/y movement to provoke intermittent breaks in the wire - nothing

- marked belt/motor position, let layers skip, compared: right motor „A Motor“ as described in the Voron Manual seems to be the culprit, although the marking on the belt was basically gone for both, but the motor position was different

Pictures:

Last edited: