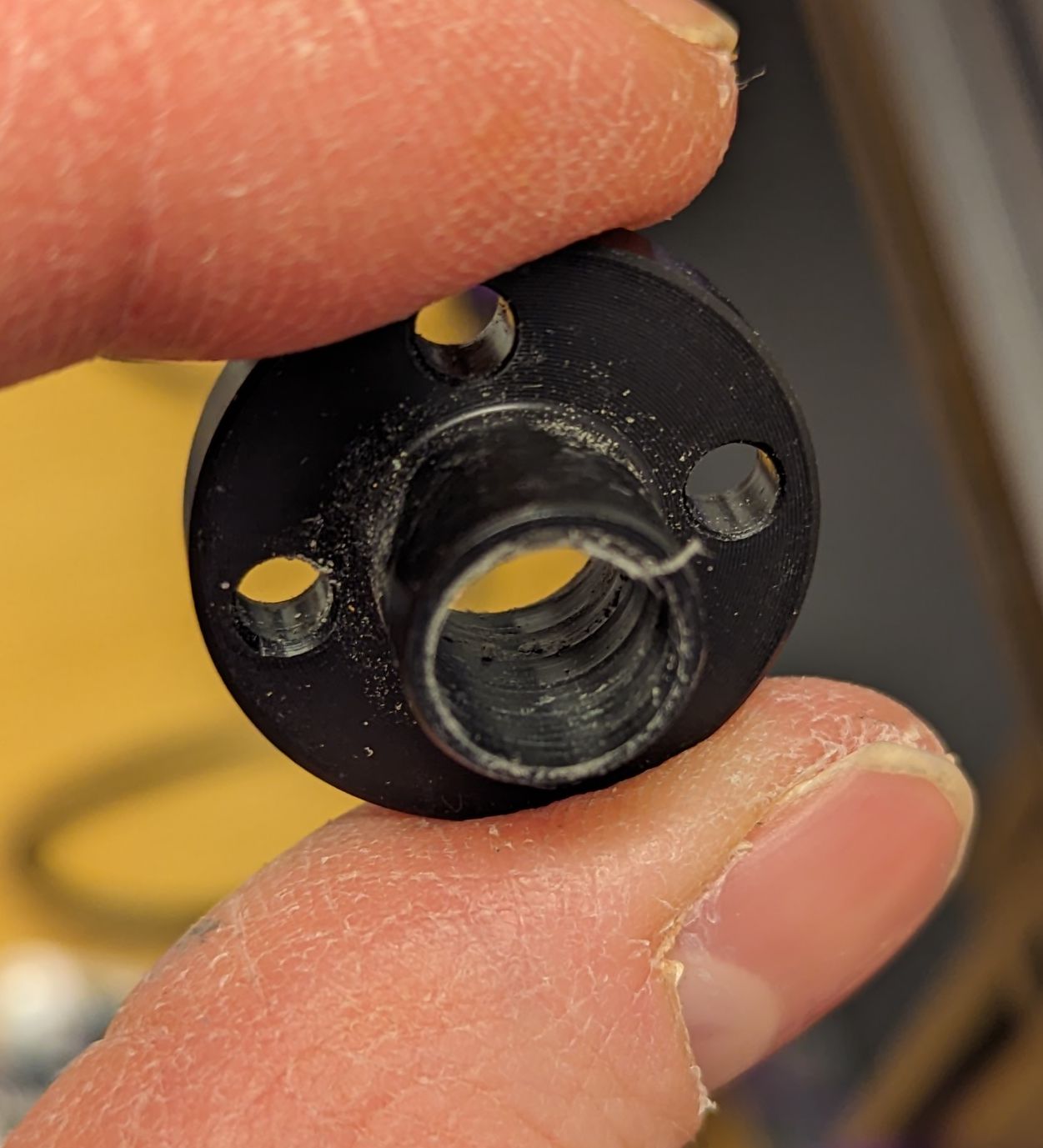

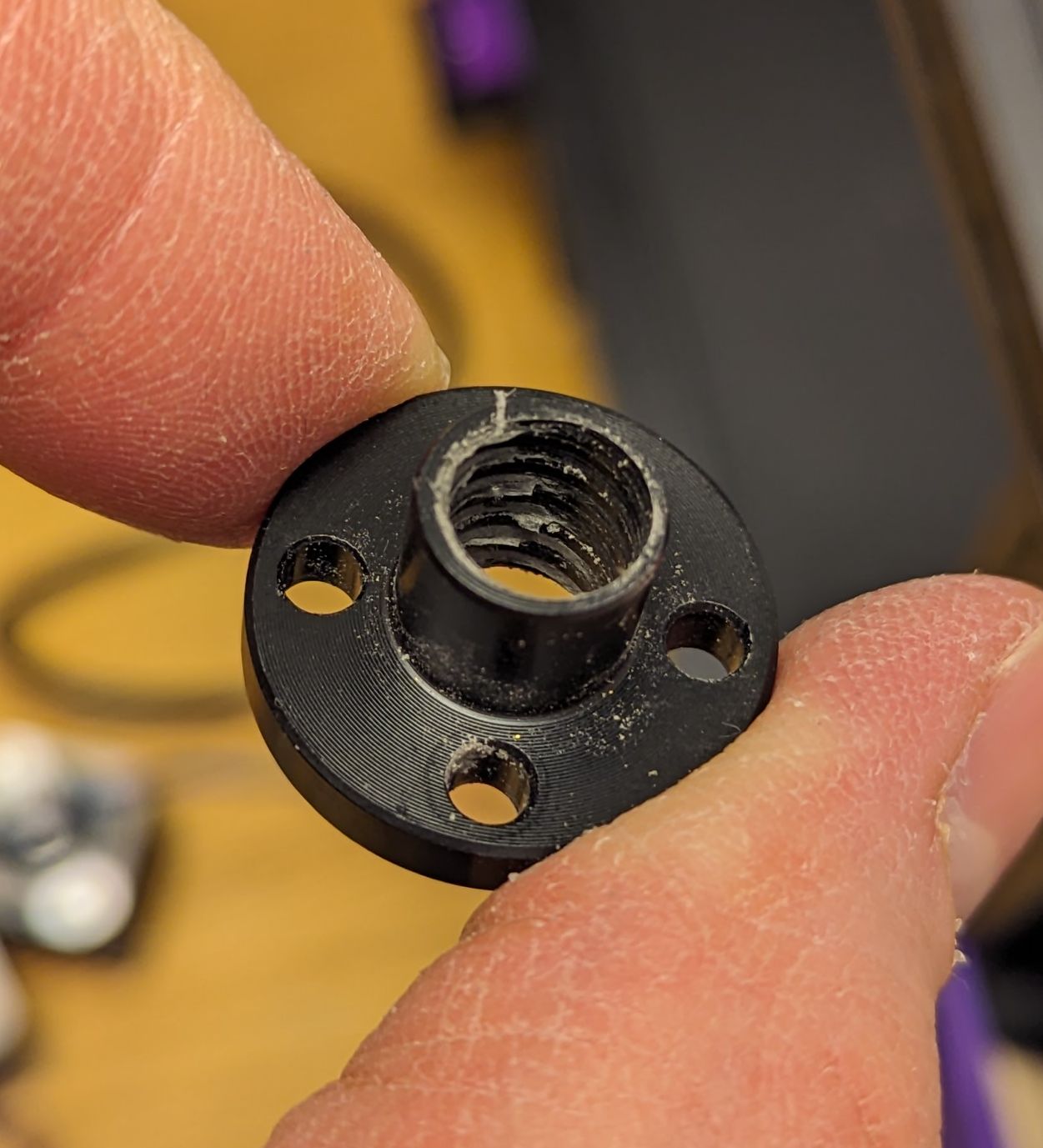

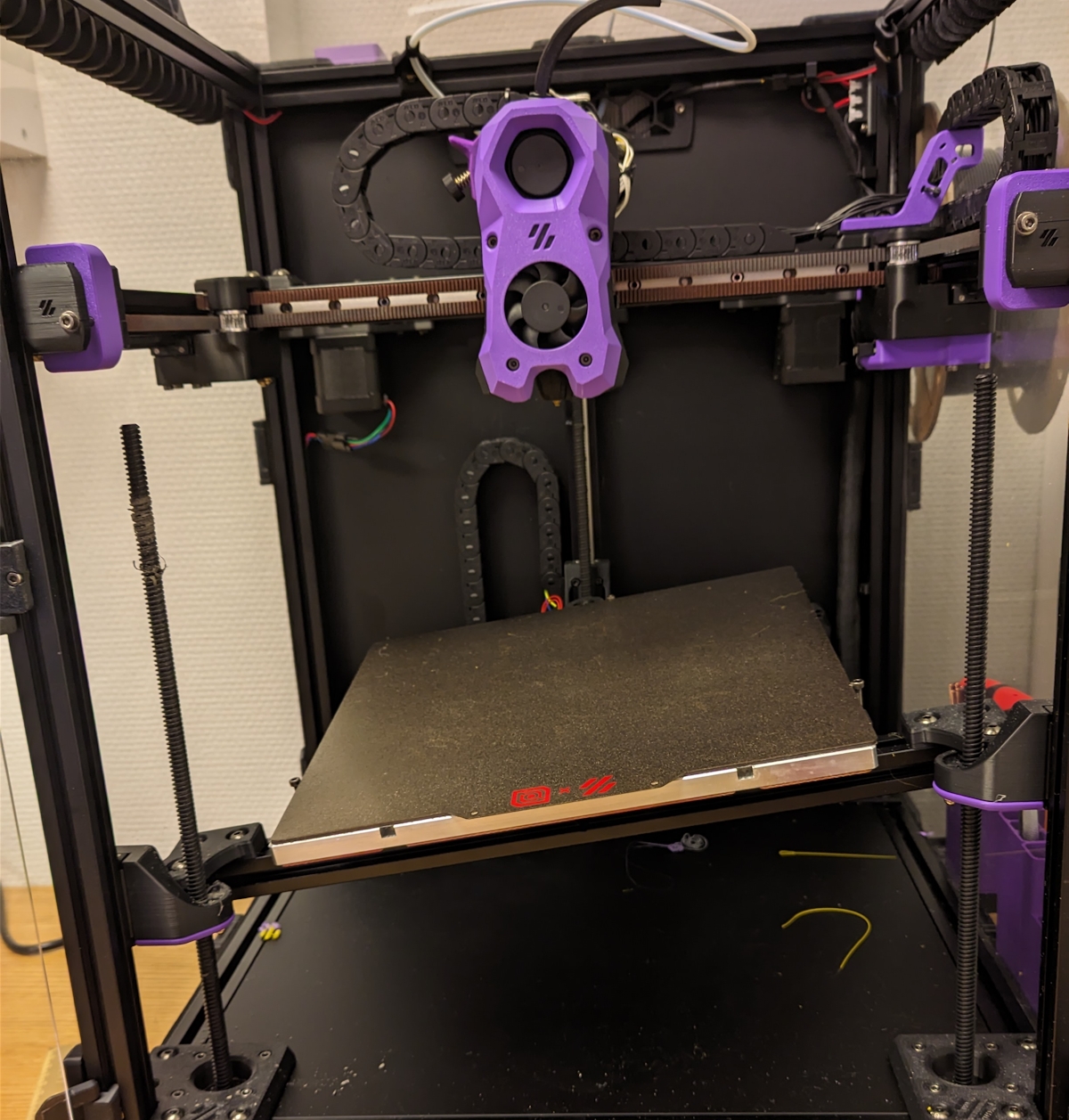

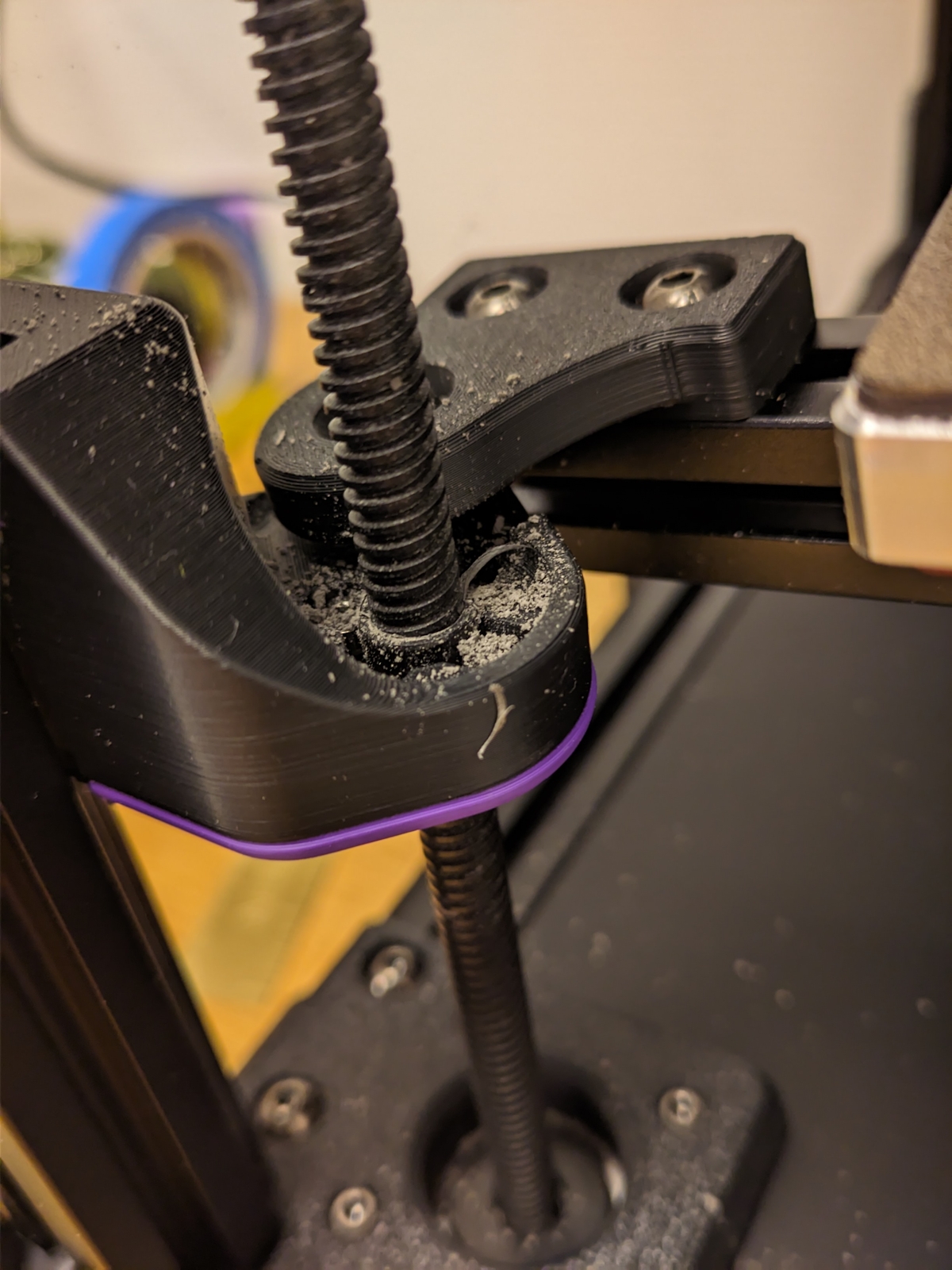

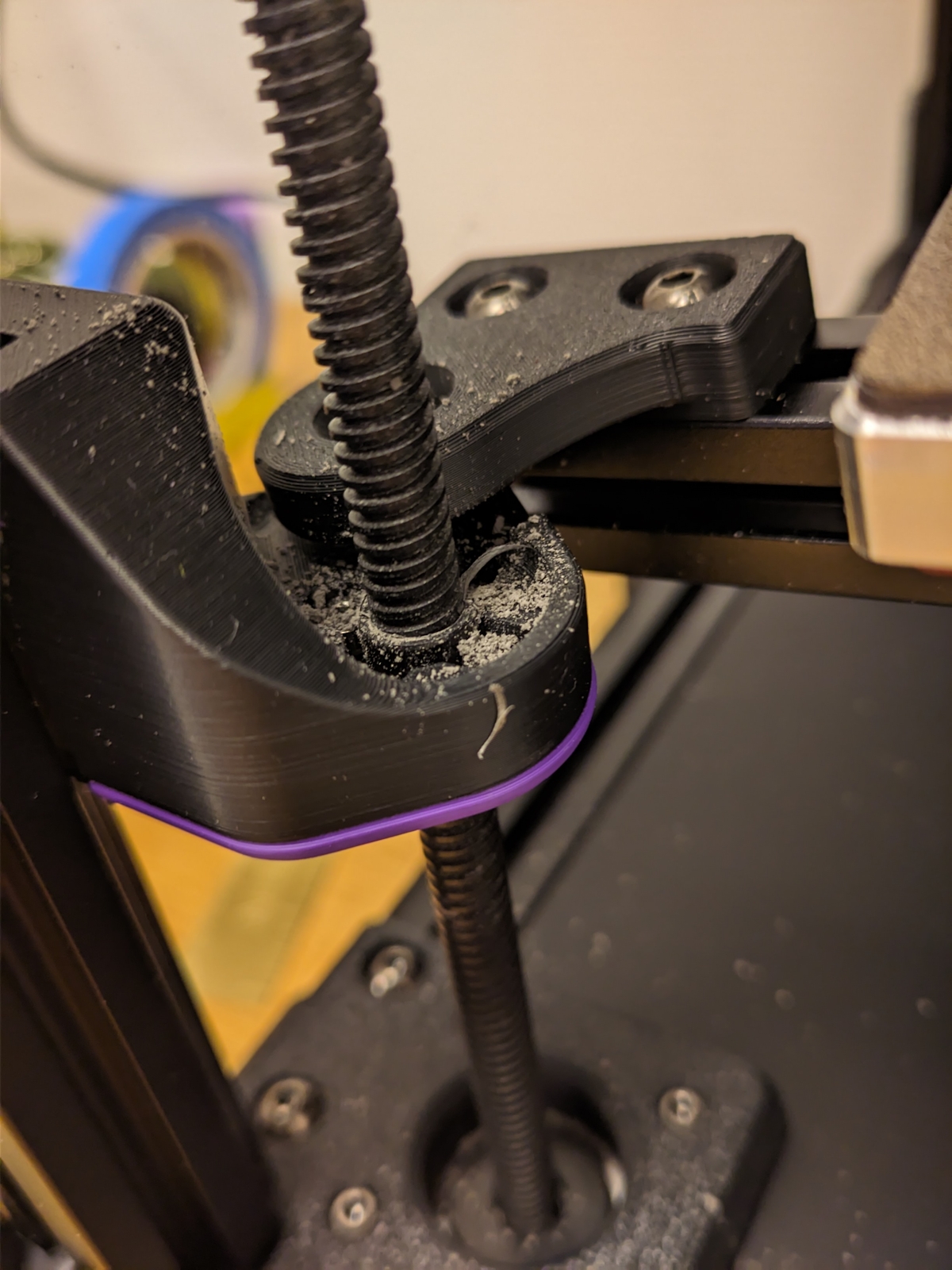

After 600 hours my Trident met a major failure with the POM nuts, where one got ground down until it completely lost the grip:

This "shouldn't happen", but there were at least two others who reported the same issue in Discord so I thought I'll start a discussion here about it.

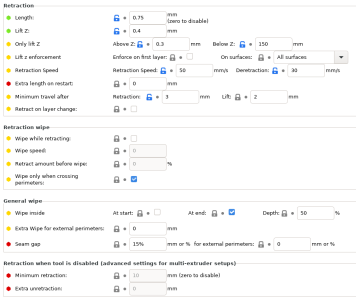

Maybe there's something that's misaligned, but I have no idea what that could be or how to check it. The nuts holding the nuts should be loose (my were a little loose, but I don't know how loose is enough). Another option is that there's an issue with the parts that came in the LDO kit?

Thinking back, the flakes started showing up soon after I started using the printer, but I didn't think it'd be something serious.

I haven't dissembled it yet, but I've ordered replacement nuts I'll try when they show up.

This "shouldn't happen", but there were at least two others who reported the same issue in Discord so I thought I'll start a discussion here about it.

Maybe there's something that's misaligned, but I have no idea what that could be or how to check it. The nuts holding the nuts should be loose (my were a little loose, but I don't know how loose is enough). Another option is that there's an issue with the parts that came in the LDO kit?

Thinking back, the flakes started showing up soon after I started using the printer, but I didn't think it'd be something serious.

I haven't dissembled it yet, but I've ordered replacement nuts I'll try when they show up.