- Printer Model

- voron2.4R

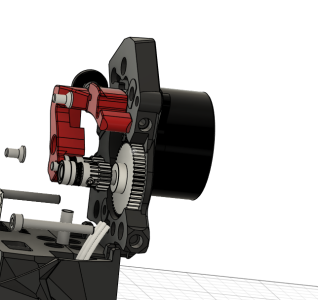

- Extruder Type

- Other

- Cooling Type

- Other

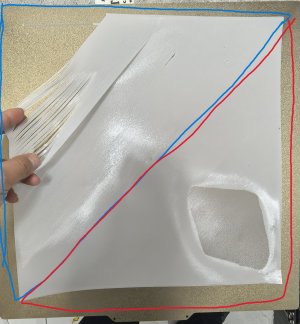

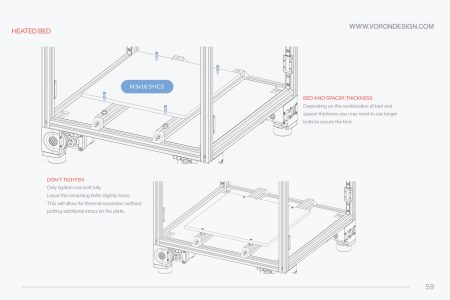

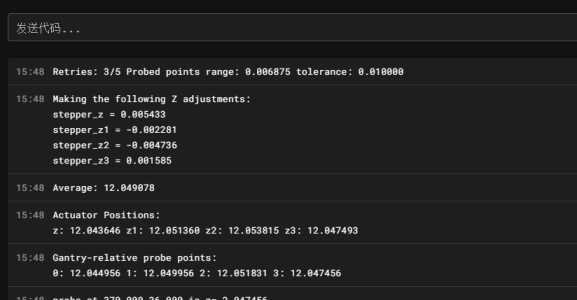

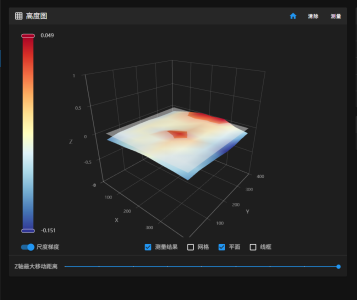

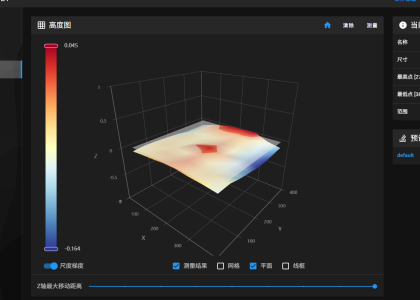

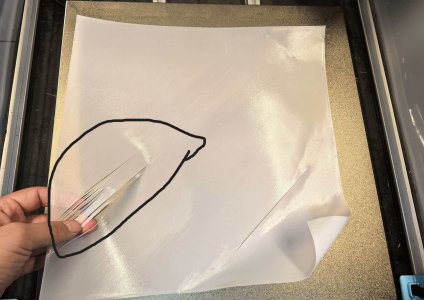

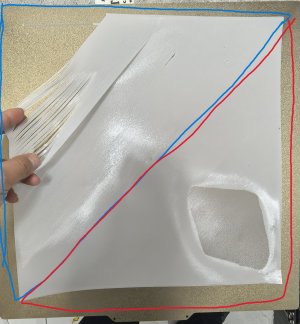

This printer has been running for over a year and hasn't been able to print for many hours. Recently, the first layer of printing has suddenly stopped. The z-offset and mesh bed have been recalibrated, and every time they print, the top left corner splits, while the bottom right corner is always good. I don't know why, but the z-offset and mesh bed have been calibrated several times。400X400X400

OrcaSlicer software G-code

M190 S[bed_temperature_initial_layer_single]

M109 S[nozzle_temperature_initial_layer]

PRINT_START EXTRUDER=[nozzle_temperature_initial_layer] BED=[bed_temperature_initial_layer_single]

; You can use following code instead if your PRINT_START macro support Chamber and print area bedmesh

; PRINT_START EXTRUDER=[nozzle_temperature_initial_layer] BED=[bed_temperature_initial_layer_single] Chamber=[chamber_temperature] PRINT_MIN={first_layer_print_min[0]},{first_layer_print_min[1]} PRINT_MAX={first_layer_print_max[0]},{first_layer_print_max[1]}

OrcaSlicer software G-code

M190 S[bed_temperature_initial_layer_single]

M109 S[nozzle_temperature_initial_layer]

PRINT_START EXTRUDER=[nozzle_temperature_initial_layer] BED=[bed_temperature_initial_layer_single]

; You can use following code instead if your PRINT_START macro support Chamber and print area bedmesh

; PRINT_START EXTRUDER=[nozzle_temperature_initial_layer] BED=[bed_temperature_initial_layer_single] Chamber=[chamber_temperature] PRINT_MIN={first_layer_print_min[0]},{first_layer_print_min[1]} PRINT_MAX={first_layer_print_max[0]},{first_layer_print_max[1]}