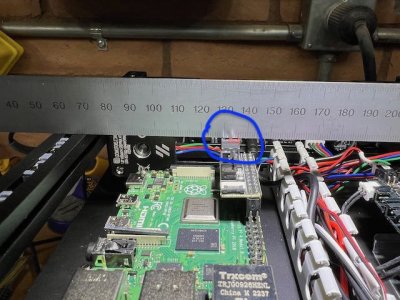

I placed the mid-panel, and began looking at the layout of the SKR Pico and the Raspberry Pi 4B that I purchased. The RP is not the Raspberry Pi Zero 2W which the LDO instructions seem to be assuming. My RP and the SKR Pico take the same RP mount, but only one mount and VHB DIN mount were included in the MatterHackers printed parts. And this is all that I see called out in the printed parts list in the GitHub.... Hmmmm. It would be really great to have two VHB DIN mounts and two RP/SKR Pico mounts, instead of just one.

I looked at this for a while, and tried to see if any of the other mounts in the printed parts I got would work. There are a lot of parts for electronics mounts, but none would work with the RP 4 hole pattern. I decided to go to my local maker space to print the mount and VHB DIN mount in PLA, with the intent of reprinting them in ABS once the printer is complete, and I can print in ABS.

Thinking about this later, I decided to search for DIN mounts available commercially. Amazon had 4” long aluminum DIN rails, available for next day delivery, for $6. I hit the “buy” button -- these are cheap enough to throw away if they don't work. If they do work, I won’t have to worry about getting a PLA DIN mount dislodged from VHB tape in order to replace it with ABS.

When the he Amazon DIN rails arrived, I found they fit the printed DIN clips just fine, though I had to trim the lengths. But they’re about 1mm taller than the printed parts. I think the printed VHB DIN mounts are a bit thinner to account for the thickness of the VHB tape which would be used to mount them. I think I can keep the design height by just drilling the mid plate and screwing in the aluminum DIN rails. I also tried a commercially available Raspberry Pi DIN mount, but this raised the Pi so far the back panel wouldn't be able to be installed.

Finally, I had the idea of asking MatterHackers if they could do a custom print of another DIN mount and rail. MH was quite helpful, and printed the extra parts I needed quite cheaply. I also had them print the Mornsun PSU cover, which is an optional printed part for the LDO kit. The printed parts arrived in two days. I decided to keep the aluminum DIN rails, even though mounting them required drilling a couple of extra holes in the mid-panel.

I also decided that I wanted to mount the PSU with screws rather than VHB tape, primarily because I wanted to be able to remove the PSU more easily later. To find where to drill the holes, I placed a sheet of paper on the bottom of the PSU, and rubbed it with a pencil. The screw locations show nicely in the pencil rubbing, and the paper became my drilling template. I did have to go to the hardware store for screws, as the holes in my Mornsun PSU take M4 screws.

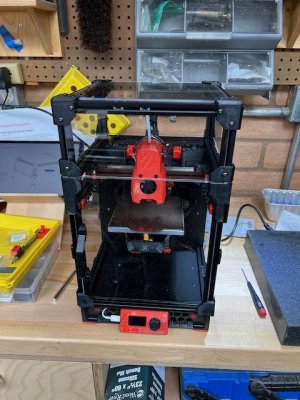

With everything now mounted, I routed and connected the wiring. This went pretty well. I found that a pair of dikes cuts the cable channel more easily than a jigsaw or a hacksaw, and is a cleaner cut to boot. Everything is now connected except for the power to the Raspberry Pi, which has me scratching my head a little.

I'm quite fortunate to have a quality control inspector purring at the assembly progress.