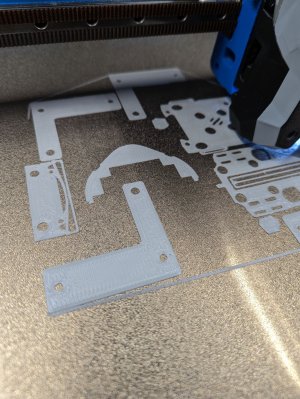

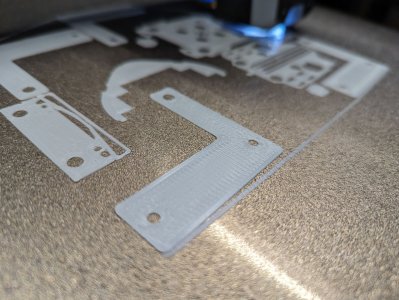

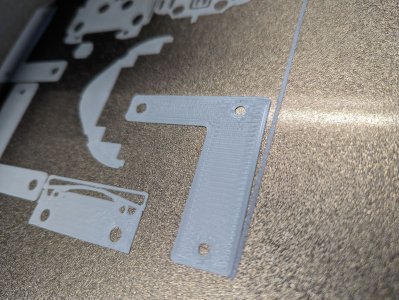

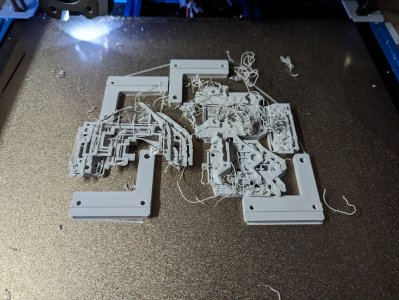

I'm having a really hard time with parts detaching and prints failing.

This is a new V2.4 LDO kit, printing ABS, bed at 110c. Good first layer squish. Bed was cleaned with soap and water and left to dry, untouched after.

What am I missing here?

BED:

Clean that with a scrubbie , not just soap and water, it makes a big difference.

Is your bed level to the extruder? This doesn't mean just the plate.

Your printer is enclosed. Voron X and Y gantry extrusions

curve when they are 50 degrees (BiMetal effect).

Then your 2.4 is warmed up fully, first layer might have insufficient squish in lots of places even with a dead flat plate. Result is your extruder knocks the parts off when they get taller and a corner lifts.

You can fix this with BACKERS, or implementing a bed mesh to accommodate it.

Bed temp : 110 might be kinda hot, magnets start losing strength after 100, your PEI steel could be lifting a bit cause parts to get knocked off.

Or it might be ok. I have no idea what magnet you bought . Some are much better than others. Try 100?

Filament: This makes a really big difference. Hotter=better adhesion , FIRST LAYER. If you use superslicer, this setting is in FILAMENT SETTINGS:FILAMENT

make the

first layer hotter , try 15 deg hotter, or 20. You didn't say what you are printing at... assuming you did a temp tower

Superslicer "Only retract when crossing perimeters" Try turning that off, can make bumps the extruder can catch on

Printer Settings - Extruder - Lift Z , Try turn that ON .4mm. Both these prevent the extruder from skating on, catching bumps, things go flying.

(later, when you have filament calibrated perfectly etc, you can try turning these back on and off)

Last , when I am printing stuff I just DONT WANT to redo , maybe the bottom has not so much contact, or I am printing with my cheap ECO-ABS

I'll turn on a BRIM. Guarantee there is no corner lift, nothing for the extruder to whack into, cheap insurance