Hi

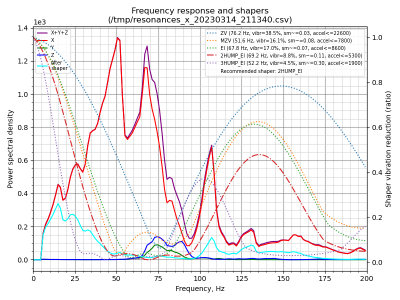

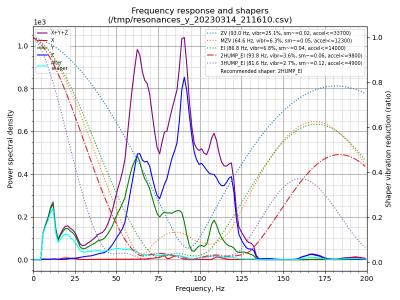

Just building a new 2.4, 300x300. I have set up input shaper with an ADXL345 but the results are absolutely awful. It is a self sourced build with Hiwin rails, quality stainless bolts, Gates belts, NJK bearings everywhere so I was expecting it to be quite good but was shocked by how bad the results are. I have made sure everything is tight, there is no movement at the toolhead, it seems really firm. The belts are tight, all grub screws are tight with loctite. The frame is very square, virtually a hairs width in any direction, the printer is on a firm base with TPU feet to help with vibrations. The Y shaper is showing lots of movement on Z but I can't really see that when looking at it. Any help would be appreciated, many thanks.

Just building a new 2.4, 300x300. I have set up input shaper with an ADXL345 but the results are absolutely awful. It is a self sourced build with Hiwin rails, quality stainless bolts, Gates belts, NJK bearings everywhere so I was expecting it to be quite good but was shocked by how bad the results are. I have made sure everything is tight, there is no movement at the toolhead, it seems really firm. The belts are tight, all grub screws are tight with loctite. The frame is very square, virtually a hairs width in any direction, the printer is on a firm base with TPU feet to help with vibrations. The Y shaper is showing lots of movement on Z but I can't really see that when looking at it. Any help would be appreciated, many thanks.