Coyote

Well-known member

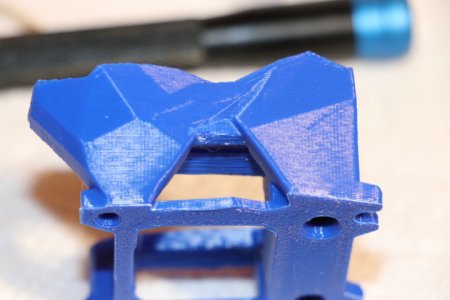

Any suggestion on how to improve quality of my stealthburner_printhead_revo_voron_rear_cw2.stl? Functionally it works but sure is ugly. This is the only printed part I seem to have this quality issue. I printing on a Prusa Mk3 using Prusaslicer and Hatchbox ABS. I have printed at various temp. The part shown here was printed at 240C but I have printed between 230-250C with same results. I have tried adaptive layers but I think it is of worse quality. The temp tower I printed for the AB I'm using seems to have the best overall print at 235C. Anyone have a suggestion of a slicer setting that might help? I have tried many. Is this just a hard part to print well? Is the transition from printing the overhang to the thin wall a problem? As I said, functionally the part works. BTW, I also tried support for just the bridge under the thin wall with no better result.